Unveiling the Reign of Fiber Lasers in Industrial Metal Cutting

In the realm of industrial metal cutting, traditional CO2 lasers have long reigned supreme. However, the emergence of fibre laser technology has ushered in a new era, where fibre lasers decisively outshine their CO2 counterparts across critical metrics crucial for modern metal fabrication.

Precision at Unmatched Speeds:

Fiber lasers produce a highly focused beam with a shorter wavelength compared to CO2 lasers. This results in a narrower kerf width and higher energy density at the focal point, enabling impeccably precise cuts even on thin sheet metal. Moreover, fibre lasers achieve cutting speeds that far surpass those of CO2 lasers, leading to significantly higher throughput and production efficiency.

Solid-State Dominance:

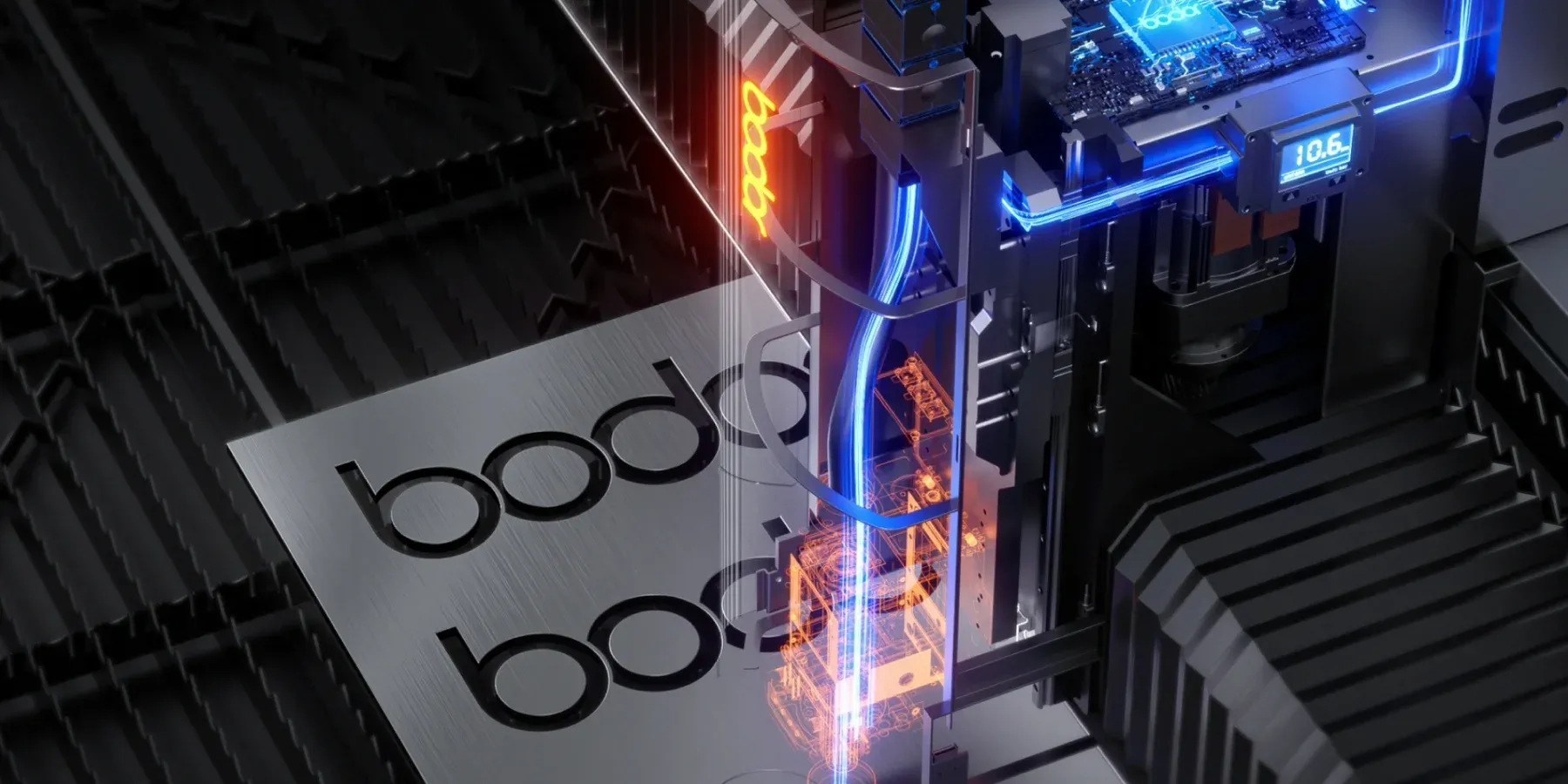

Unlike CO2 lasers, which rely on complex gas mixtures and intricate resonator systems, fibre lasers utilize a solid-state gain medium housed within a fibre optic cable. This eliminates the need for cumbersome gas handling systems and high-maintenance components. The stability of fiber optic beam delivery ensures exceptional cutting consistency and minimal operator intervention, thereby reducing maintenance costs substantially.

Champion of Energy Efficiency:

Fiber lasers boast superior wall-plug efficiency, converting a significantly higher percentage of input power into usable laser light compared to CO2 lasers. This results in lower operating costs and a reduced environmental footprint, aligning perfectly with the energy-conscious manufacturing landscape of today.

Material Versatility:

With a shorter wavelength, fibre laser radiation offers superior absorption characteristics across a broader range of metals. Unlike CO2 lasers, which struggle with reflective materials like aluminium and copper, fiber lasers efficiently couple their energy into these metals, yielding clean, dross-free cuts. This versatility enables a wider range of metal fabrication applications to be addressed with a single technology.

Embracing the Fiber-Optic Future:

While CO2 lasers may retain relevance in niche applications, the advantages of fibre lasers are undeniable. Their unmatched speed, precision, energy efficiency, material compatibility, and maintenance simplicity position them as the undisputed champions of modern industrial metal cutting. With advancements like Bodor lasers now reaching cutting power up to 60KW, fibre lasers effortlessly tackle thicker steel cutting challenges. As fibre laser technology evolves, its capabilities will only expand, solidifying its role as the cornerstone of future metal fabrication processes.