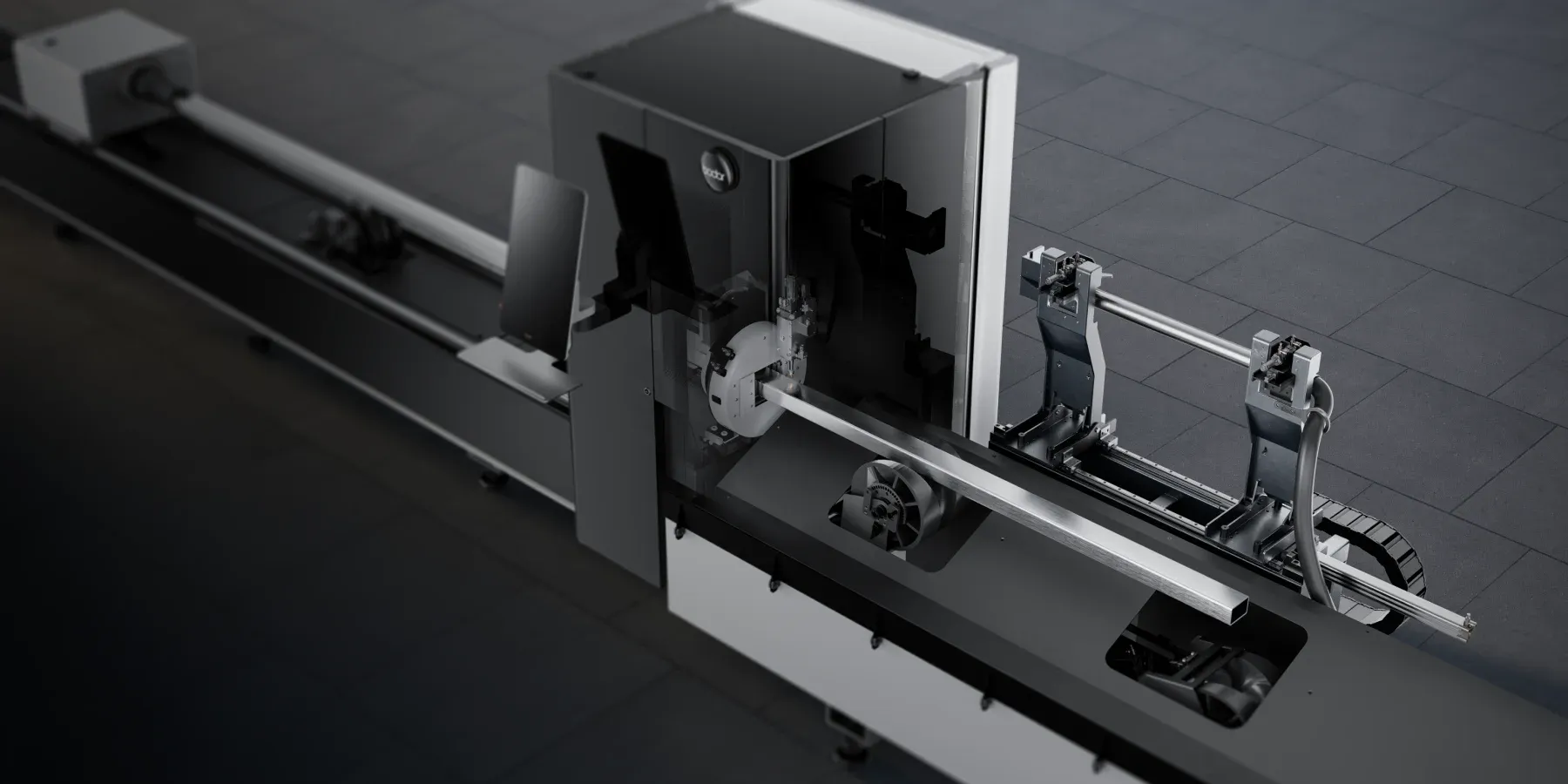

Bodor K Series Entry-Level Tube Laser Cutting Machine

The economical choice for precise tube processing. Experience excellent performance with huge savings.

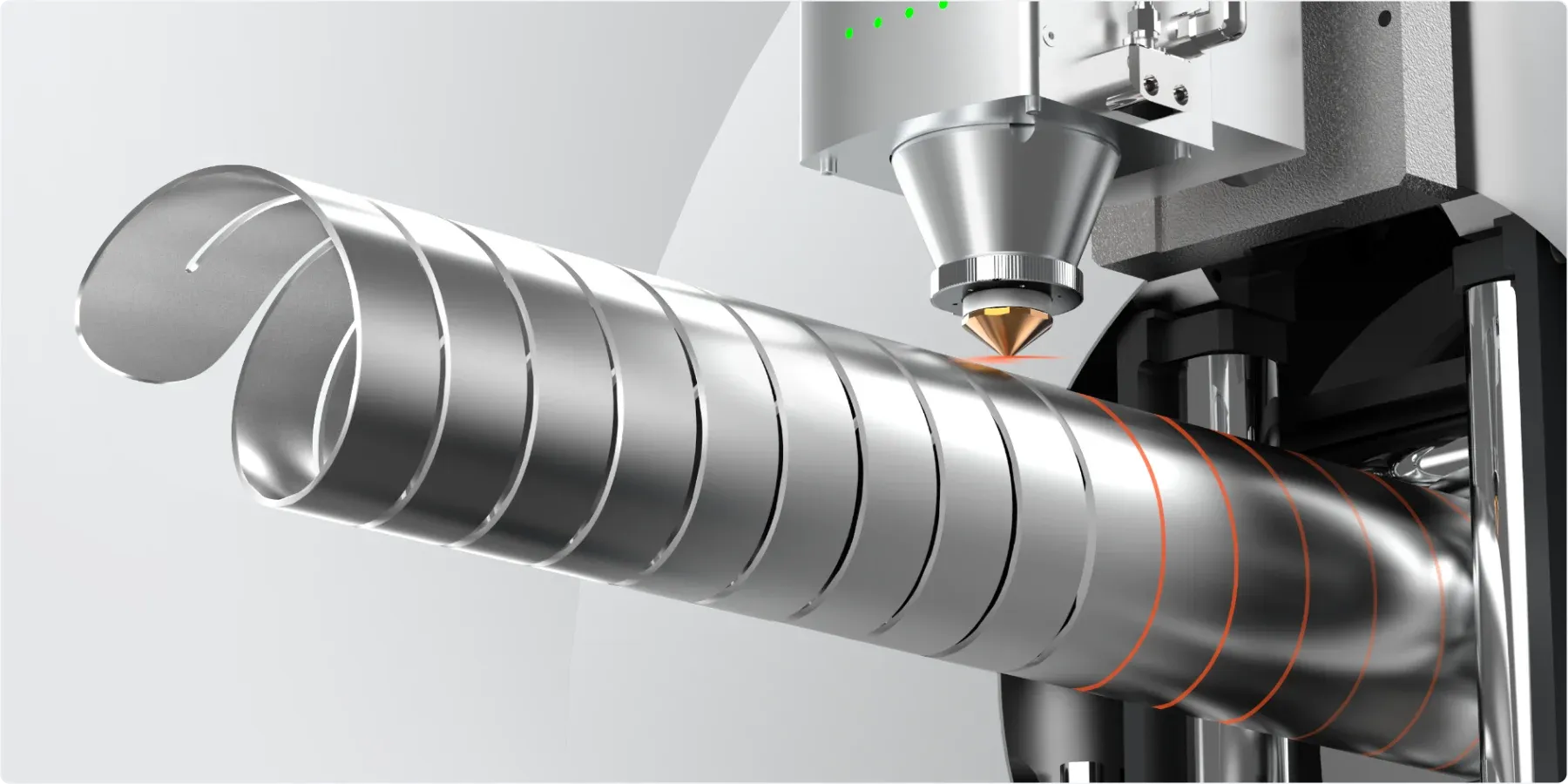

Fast cutting: No compromises on speed. K Series achieves a maximum feeding speed of 100m/min and a chuck rotating speed of 130r/min.

High level of safety: Enjoy the ease of operation. K Series enhances operating safety for all production runs by providing great accessibility to all working areas.

Automation: Automation makes operations easier. K series exhibits high productivity thanks to Bodor’s automation devices like K-Loader and K-Trans. Automation optimizes material flow and boosts output of the production line.

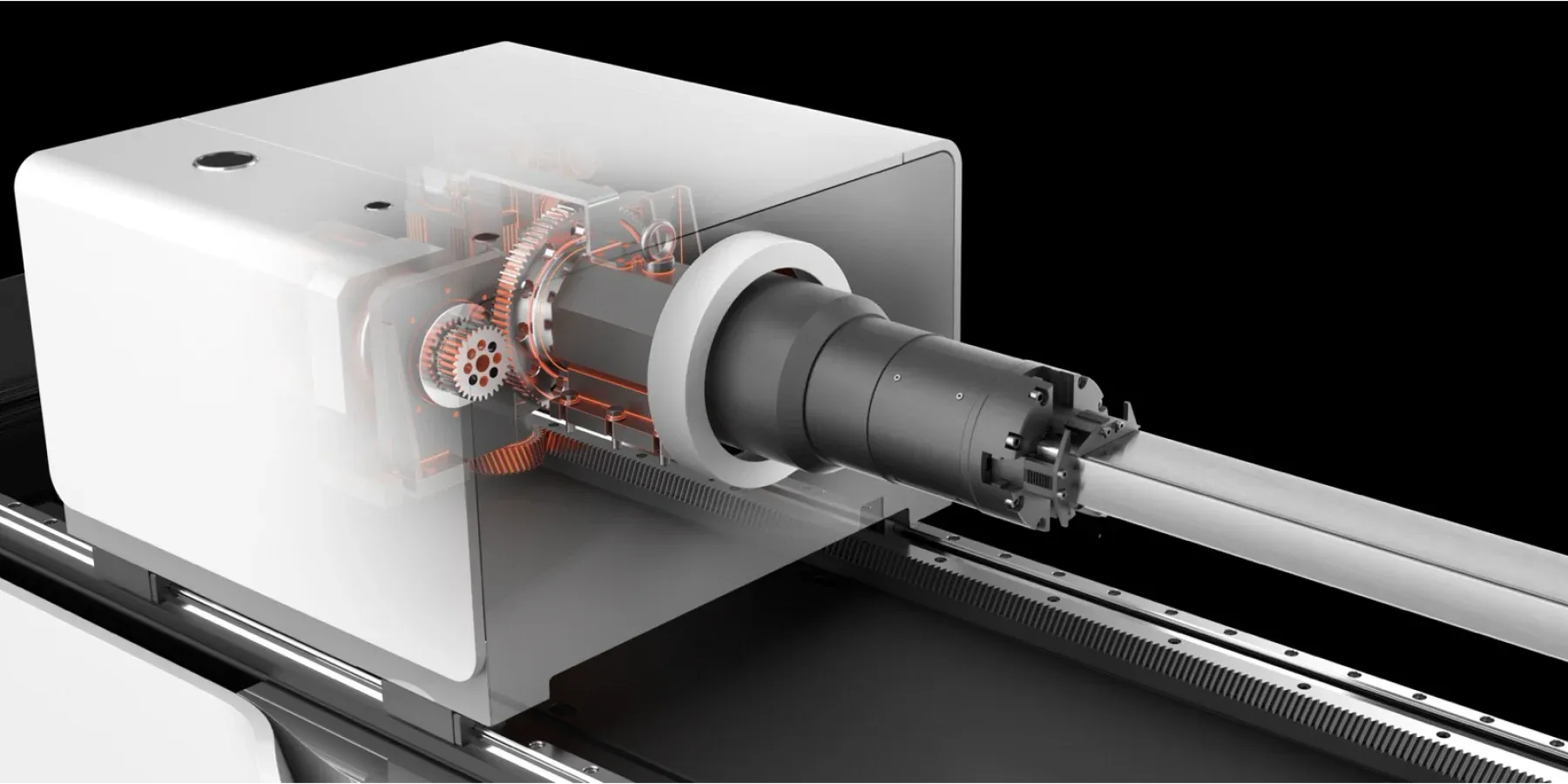

K series’ pneumatic chucks are well-suited for stable performance in dynamic applications. Each of the two chucks is able to complete clamping in just 2 seconds with a strong chucking force. It also reduces scrap to only 45 mm, limiting waste and facilitating regular on-site maintenance.

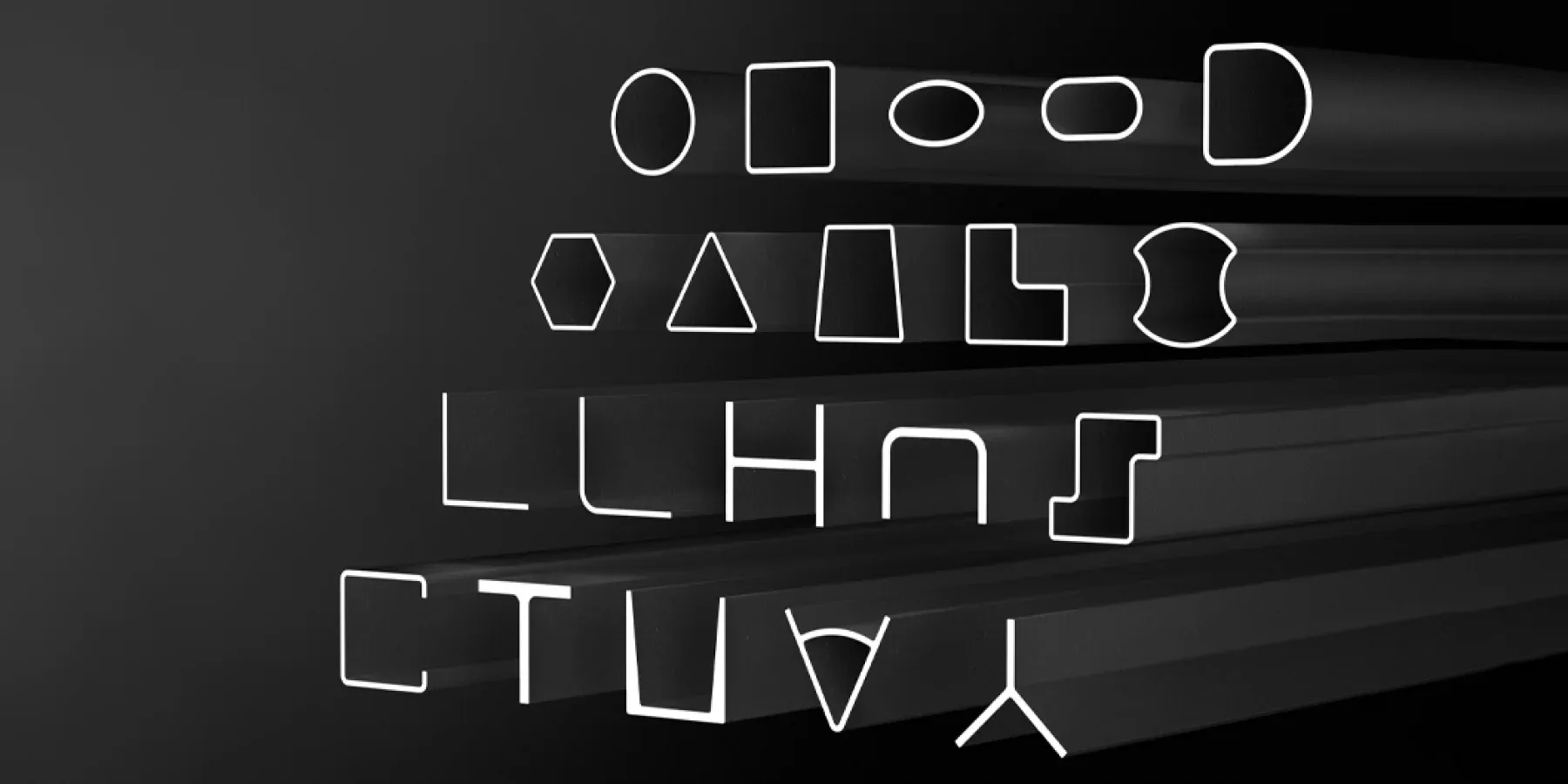

K series machines allow users to manufacture standard and customized-shaped steel tubes for their project needs. They have the capability to cut tubing in square, rectangular, flat oval, elliptical and many other custom shapes in a variety of metals.

BodorNest Tube is system designed for intelligent tube processing. It works with a diverse range of tube materials. Users can customize tube cutting layouts to fulfill different fabrication needs. This software increases material utilization rate by 15% and layout speed by 25%, facilitating the process of tube nesting. It also seamlessly integrates with other business software such as Tekla and Tribon.

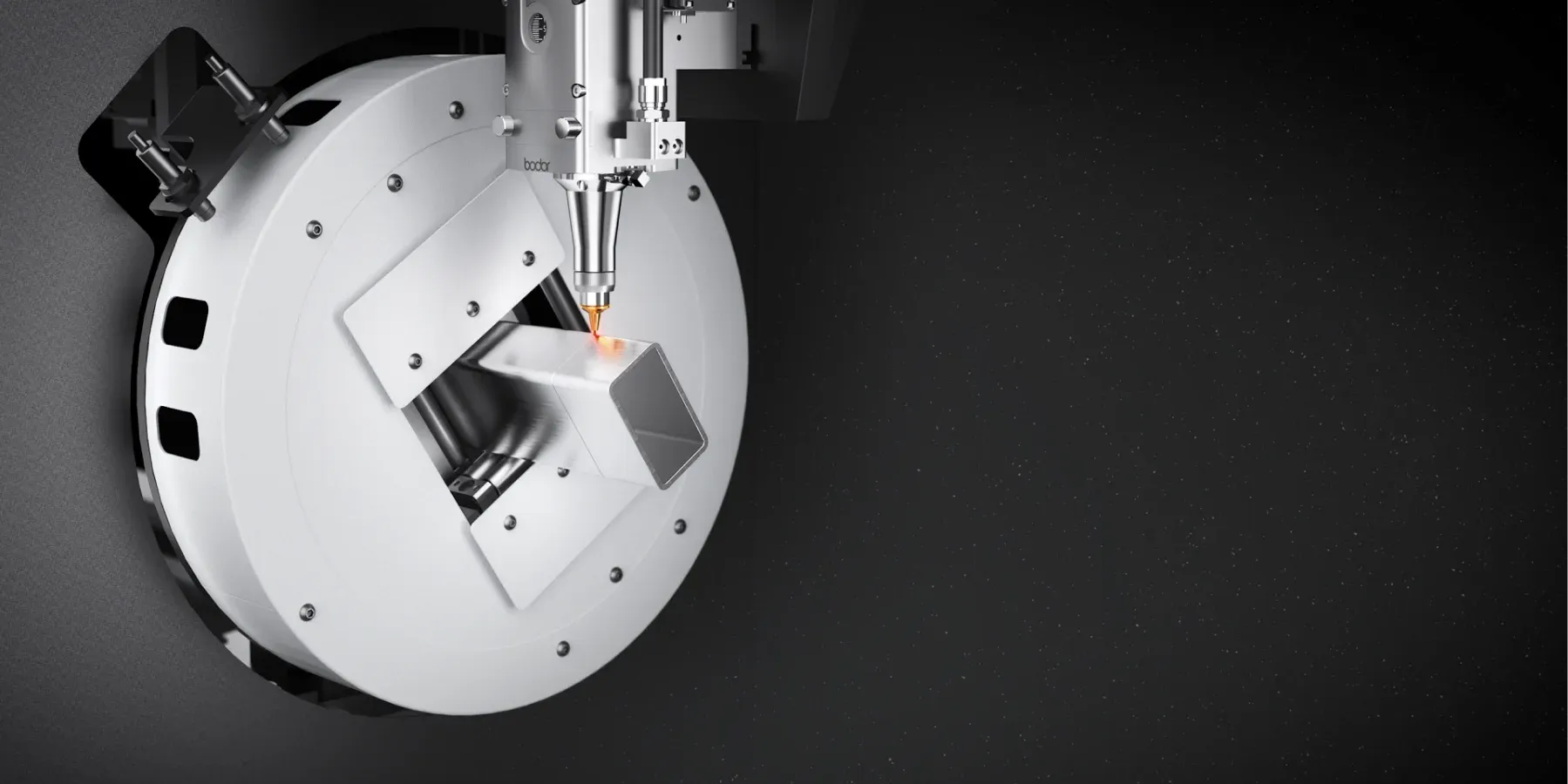

When cutting rectangular or square tubes, the K series system calculates the tube’s corner rotation radius through the function, effectively preventing collisions between the laser head and the tube, and thus avoiding any damage to the laser head.

The slag cleaning module is the latest addition to Bodor’s K1 and K2 series of tube lasers. This feature aims to keep the tube interior free of slag, debris and dust. Through suction inside the tube, it eliminates the need for post-processing cleanup and enables a more efficient production process, resulting in a clean internal surface.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!