Bodor i Series Compact Sheet Metal Cutting Machine

Explore where functionality meets space-saving.

Compact, flexible design: The i Series increases the productivity of your production line without requiring much space. The system has been designed to take up as little floor space as possible.

Eco-friendliness: The fully enclosed design leads to more economical processing and faster performance, with a much lower power consumption.

Efficiency: The i series compact system demonstrates high productivity thanks to Bodor’s intelligent functions, as they optimize material flow, boost output, and increase the operating safety of the production line.

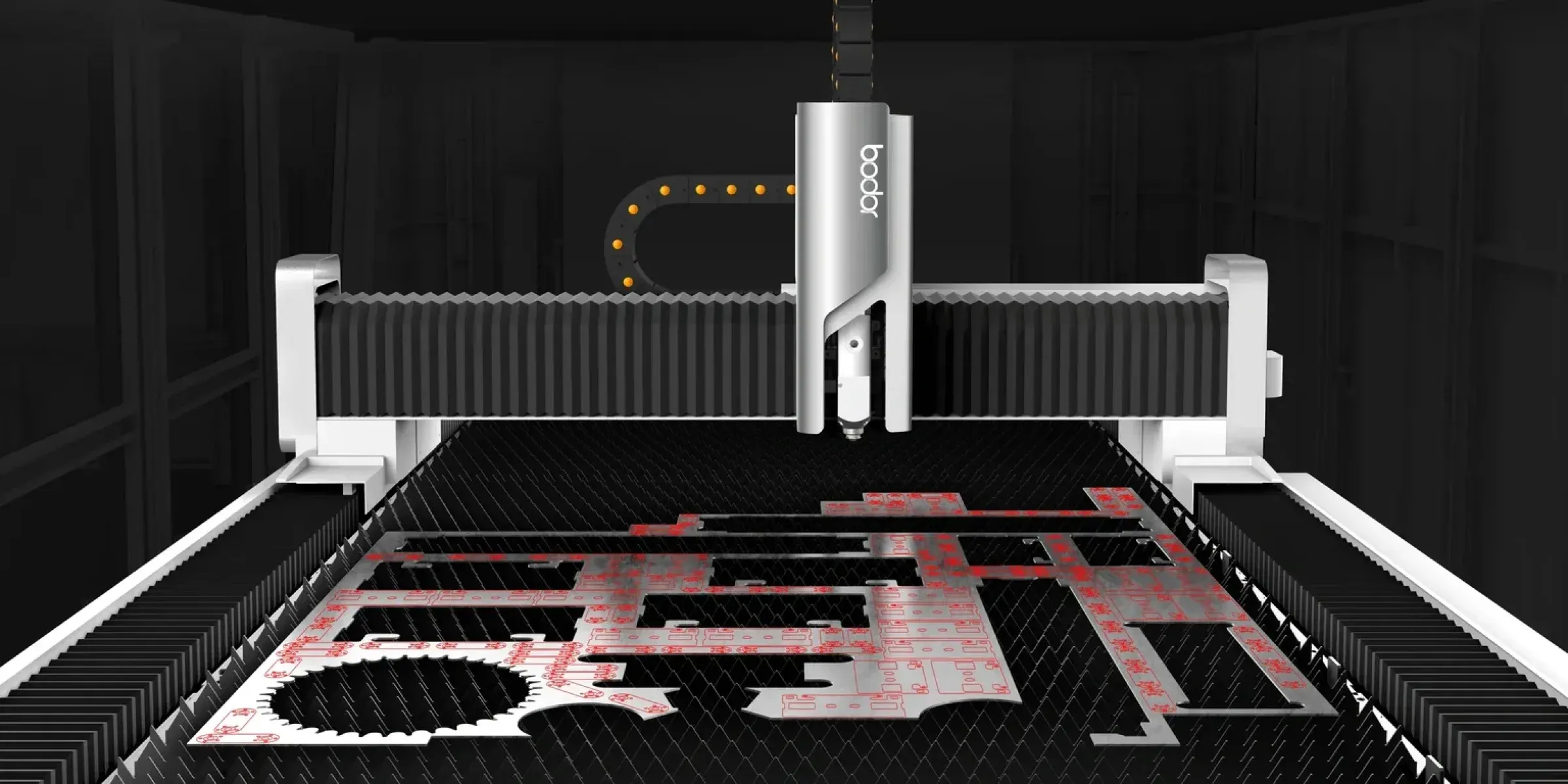

Set up your tasks ahead of time and let Dream series do the rest. Once the operation begins, it will automatically complete edge searching, range checking, and cutting one after another. With Dream series, you can finish batch production easily without any repetitive procedures.

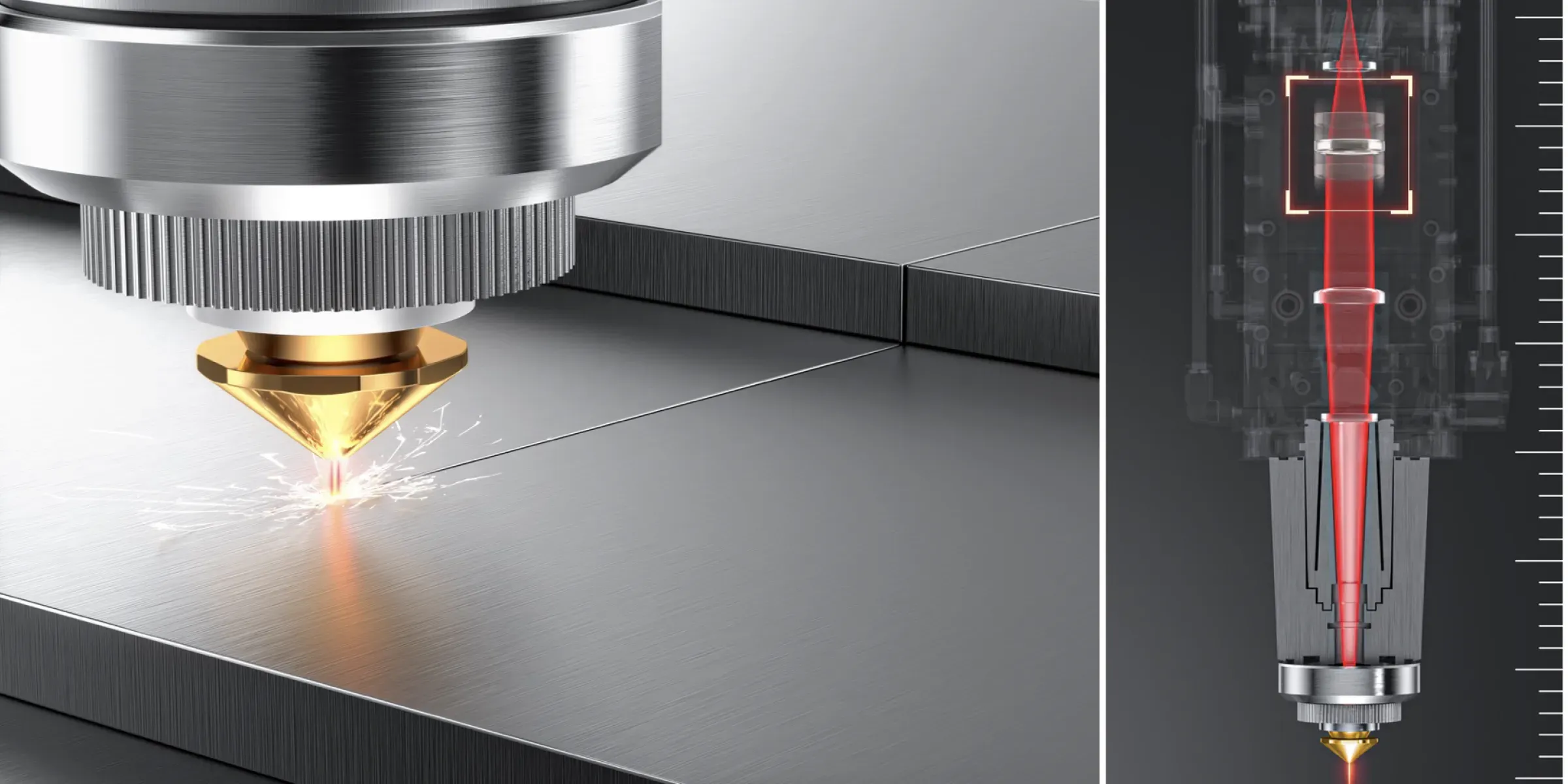

BodorGenius, Bodor’s intelligent laser head, uses sensors and algorithms to detect potential obstacles like warped edges and automatically avoids a collision. It largely ensures the stability as well as operating efficiency in the cutting process.

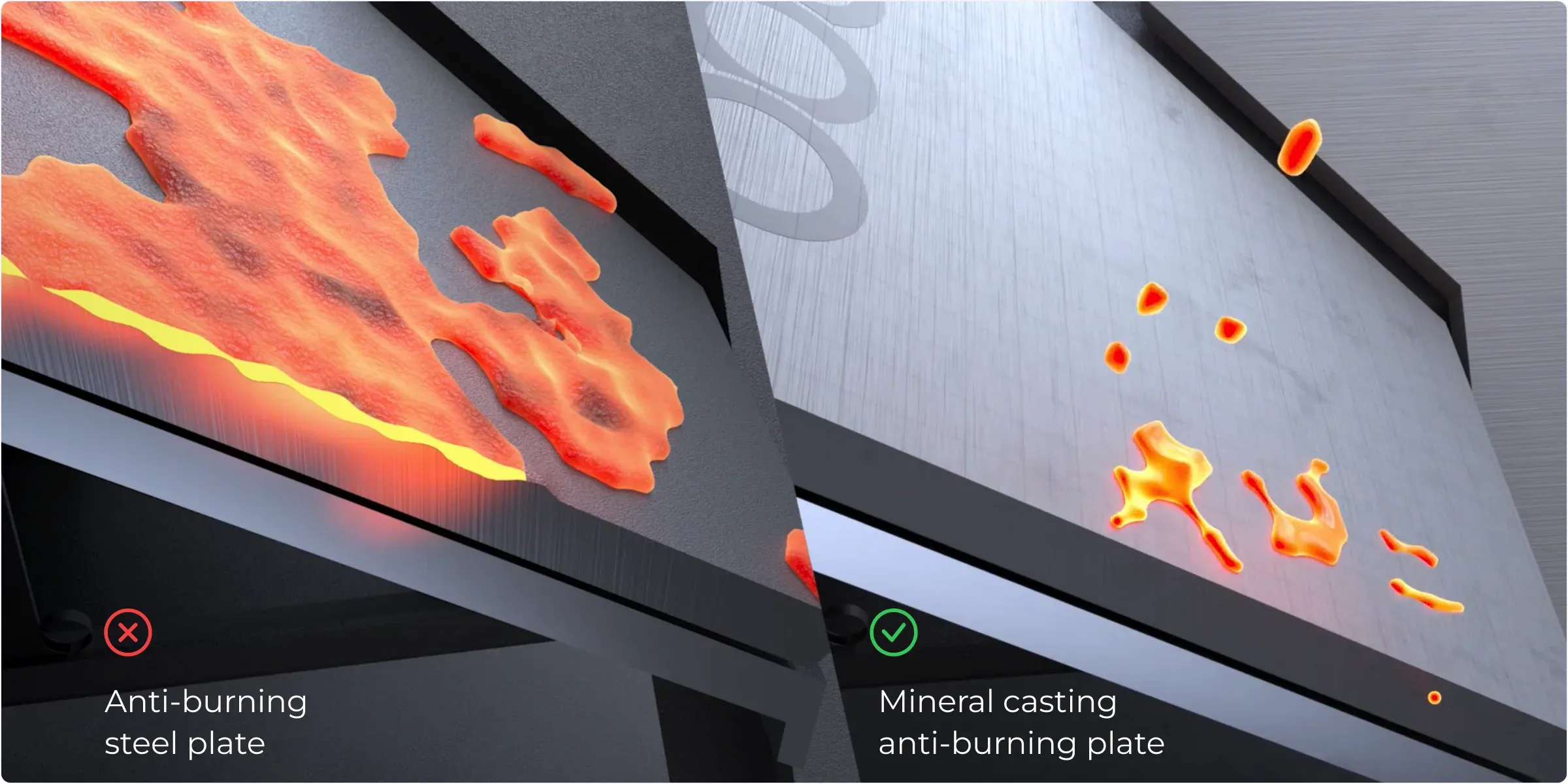

Bodor’s newly developed anti-burning plate, made by mineral casting, provides numerous advantages in slag removal, operations, modular design, fire resistance, and hardness. When in use, the plate prevents material residue and avoids heat damage to the machine bed generated by cutting, essentially lowering maintenance costs and offering better durability. Its lightweight structure also makes it easy to replace during regular maintenance.

To achieve maximum material utilization, all you need to do is uploading cutting shapes to the control system via your mobile phone. Dream series is able to automatically finish positioning as well as nesting. The higher the percentage of utilization, the better and more economical the process. Enjoy the benefits of significantly increased cost savings.

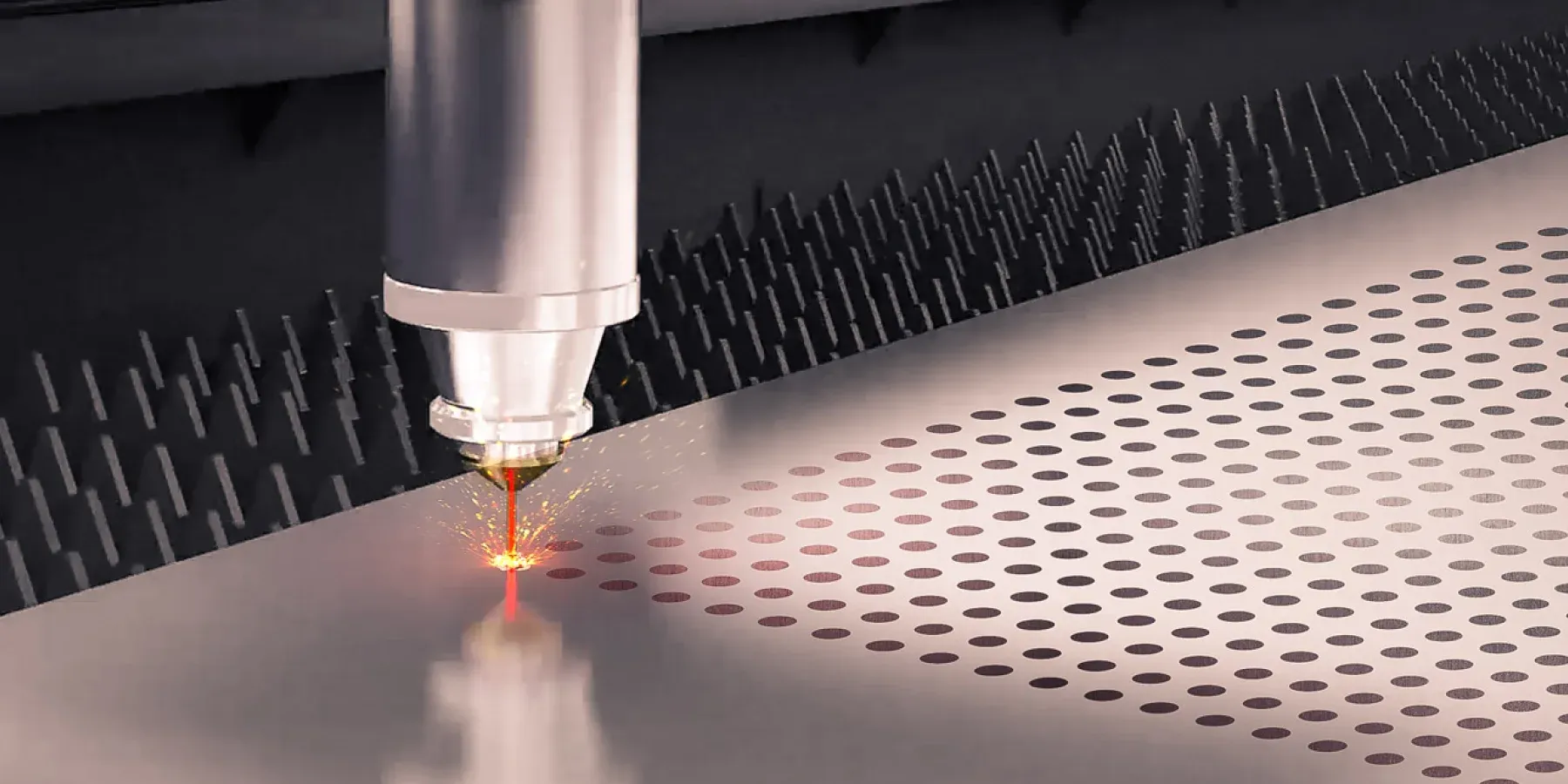

The technology offers rapid, precise piercing with a reduced amount of time. It features efficiency-monitored processes, focus adjustment, and integration with BodorGenius. This enables quick piercing in sync with the cutting head’s movement, optimizing operations for medium-thick plates without extra time or motion.

To stabilise the laser beam focal point during the cutting process, this function counteracts the adverse effects of overheating by adjusting time and temperature. It is especially applicable to cutting thick sheet metal.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!