Fibre laser cutting machines have revolutionised metal fabrication, offering unparalleled precision, speed, and versatility. But the laser itself isn’t the whole story. An often-overlooked element is the assist gas, a pressurized stream that significantly impacts cut quality, efficiency, and cost. While traditional options like oxygen and nitrogen offer distinct benefits, compressed air has emerged as a compelling alternative for many fibre laser cutting applications.

Understanding the Role of Assist Gas

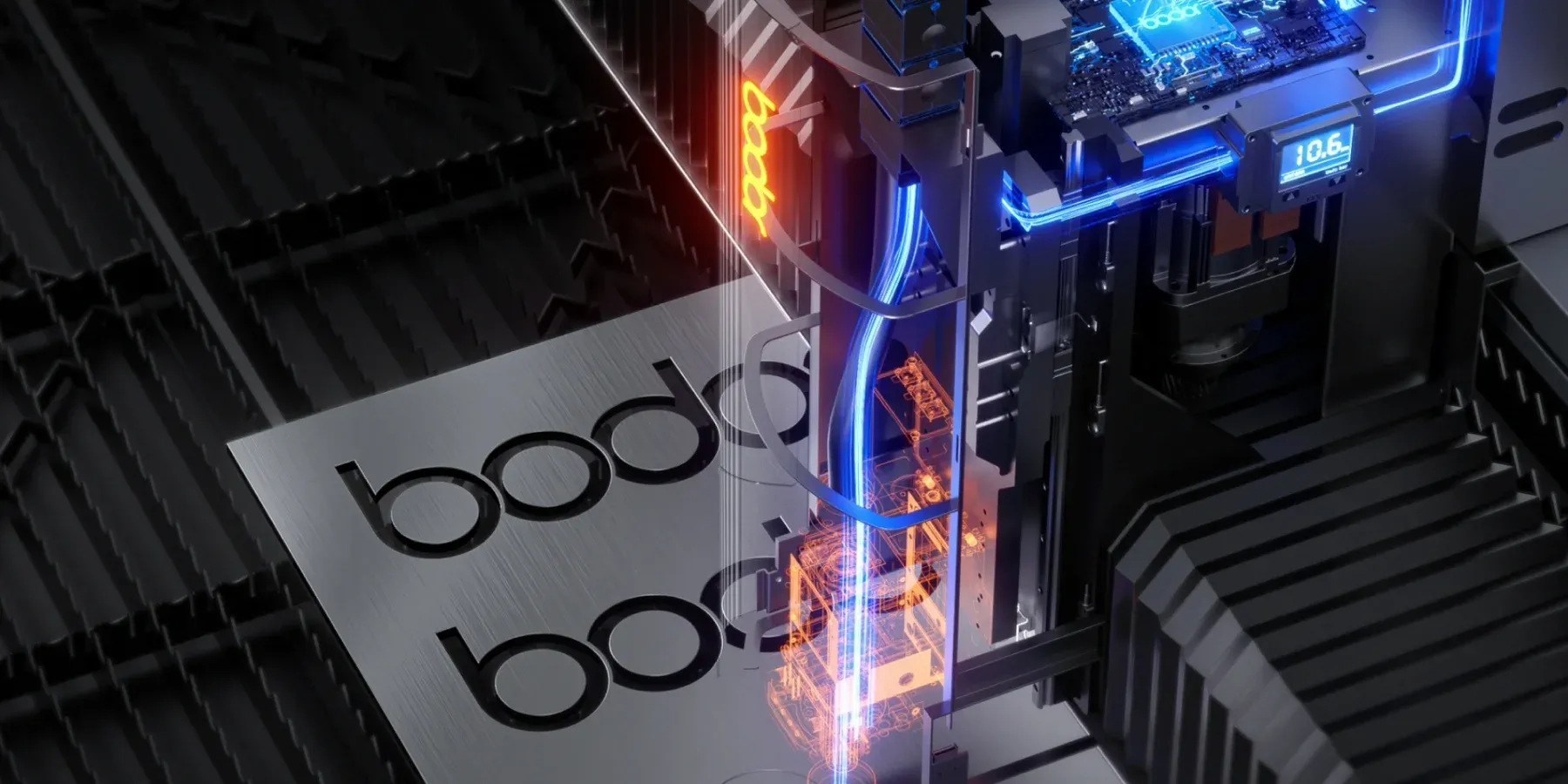

During the fibre laser cutting process, the high-powered laser beam melts and expels molten metal from the kerf, creating the desired cut. The assist gas plays a crucial role in this process by:

- Expelling molten material: The pressurised gas stream physically removes molten metal from the kerf, preventing it from reattaching to the cut edge and forming dross or slag.

- Cooling the cutting zone: The assist gas absorbs heat from the molten metal, aiding in a cleaner cut and minimizing heat distortion on the surrounding material.

- Protecting the optics: In some cases, the assist gas helps shield the laser cutting head’s delicate focusing optics from spatter and fumes generated during the cutting process.

Why Compressed Air? A Cost-Effective Powerhouse

Compressed air, readily available and relatively inexpensive, it offers several advantages over traditional assist gases:

- Cost Savings: Compared to the ongoing expense of purchasing and refilling oxygen or nitrogen bottles/ tanks, compressed air is a significantly cheaper option. This cost reduction can translate to substantial savings, especially for high-volume production facilities.

- Versatility and speed: Due to its composition (approximately 78% nitrogen and 21% oxygen), compressed air offers a degree of versatility. The nitrogen content aids in suppressing unwanted reactions during cutting of non-ferrous metals like aluminium, stainless steel and brass, similar to pure nitrogen. The presence of oxygen, however, allows for a significant speed increase when cutting mild steel compared to pure nitrogen. Even more so on higher power lasers. See charts below.

- Environmental Friendliness: Compressed air is a readily available, environmentally friendly alternative. Eliminating the need for specialized gas deliveries reduces the associated carbon footprint.

- Simplified Gas Management: Compressed air eliminates the need for dedicated gas storage tanks and complex gas delivery systems. This simplifies overall system operation and reduces maintenance requirements.

Optimising Compressed Air Assist for Fibre Laser Cutting

While compressed air offers significant benefits, it’s crucial to understand its limitations and implement best practices:

- Material Compatibility: Compressed air may not be suitable for all materials. For thicker mild steel sections or reactive metals like titanium, pure oxygen or specific gas mixtures might be necessary to achieve optimal cut quality and speed.

- Cut Quality: Compressed air may result in a slightly rougher cut surface compared to pure nitrogen, particularly on non-ferrous materials. This might necessitate minimal post-processing depending on some critical application requirements.

- Air Quality: The cleanliness and moisture content of the compressed air are critical. Contaminants like oil or moisture can negatively impact cut quality and potentially damage the laser cutting head. Utilizing high-quality air filtration and drying systems is essential.

Conclusion: A Viable Option for Many Applications

Compressed air assist offers a compelling value proposition for fibre laser cutting across various industries. Its cost-effectiveness, environmental benefits, and relative ease of use make it a strong contender for many cutting applications. For shops working with thin to medium thickness mild steel, aluminium, and other non-ferrous metals, compressed air can be a powerful tool to enhance productivity and reduce operational costs. However, a thorough understanding of material compatibility, cut quality expectations, and proper air filtration is crucial to maximizing the benefits of this versatile assist gas.