With a fully automated system, R series production line processes sheets & coils with the highest productivity.

One-stop functioning: Complete steel coil processing in one go. R series production line integrates every operation you need for your coil materials, including uncoiling, levelling, and cutting.

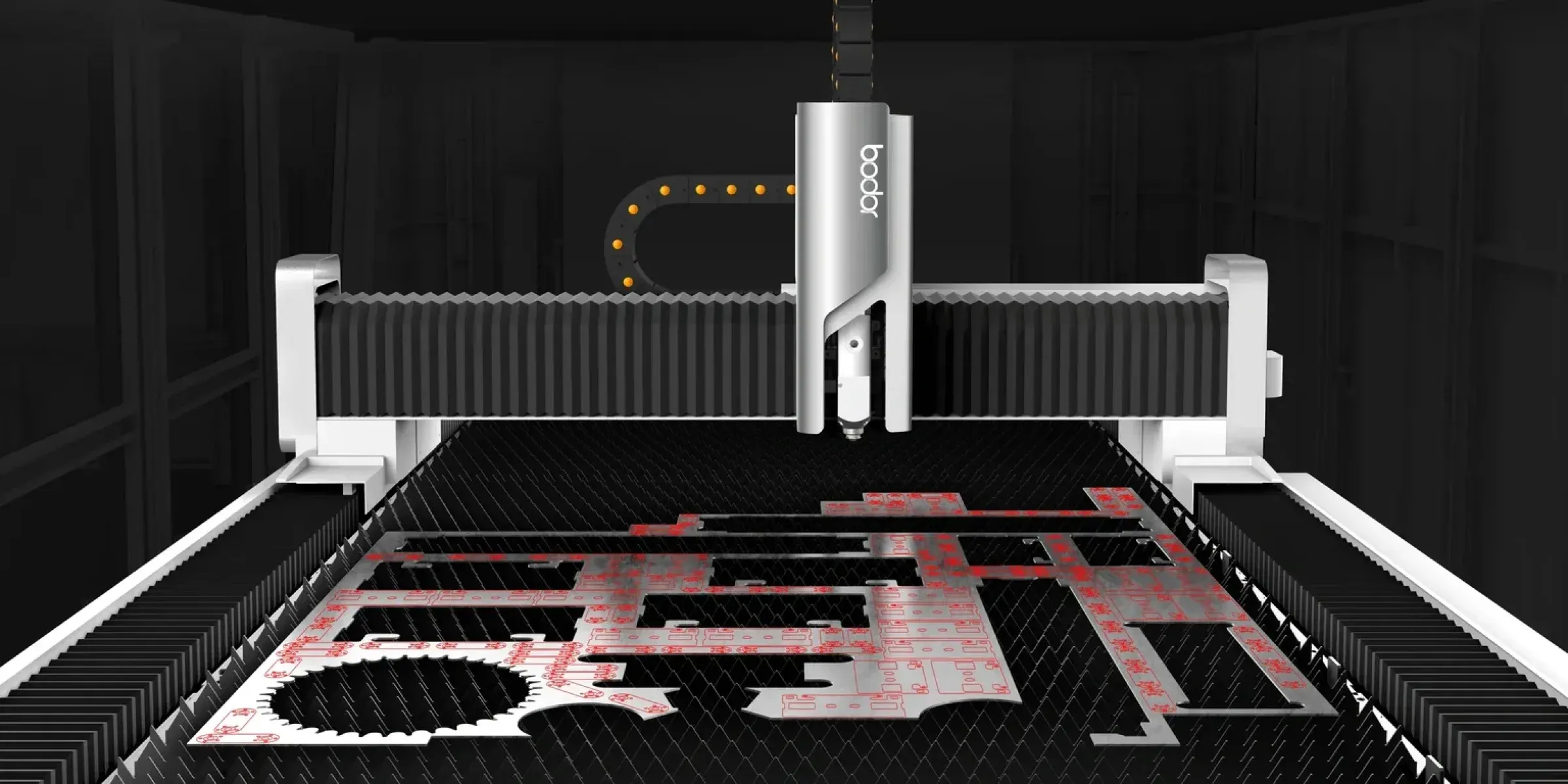

Lower material costs: Saving starts with the first cut. Continuous nesting optimally utilizes coil materials, in turn significantly reducing scrap and thus component costs.

High precision: Precise coil cutting is the success factor for efficiency. This is ensured by the R Series’s misalignment correction function.

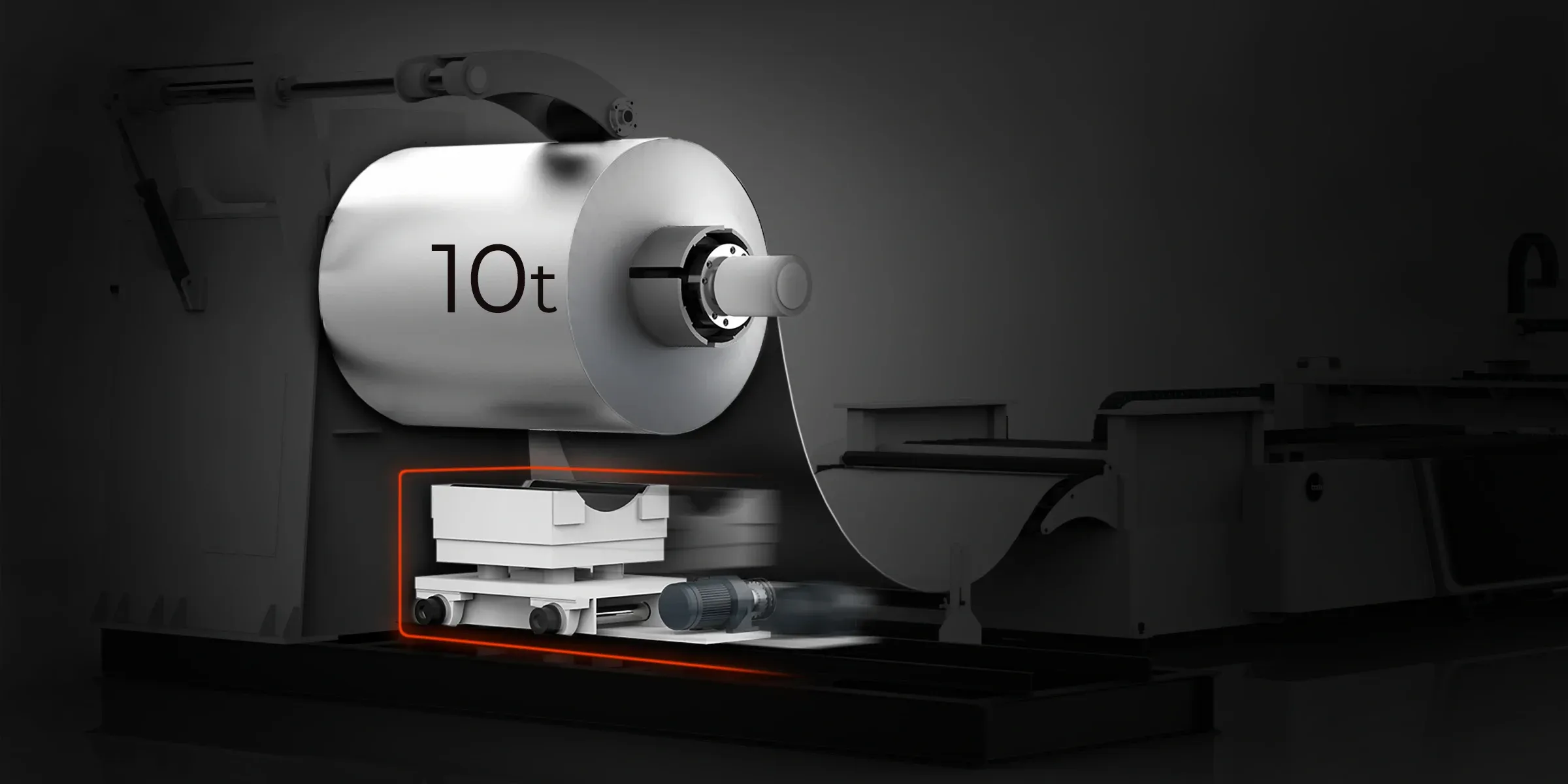

Every R Series machine line comes with a feeding trolley that holds weight up to 10t. With a moving speed up to 6m/min, it transports materials from one end to another, prepping them for the uncoiling process.

R Series is able to adjust coil length based on the size of the work piece and layout. This intelligent function significantly increases material utilization and lowers production costs.

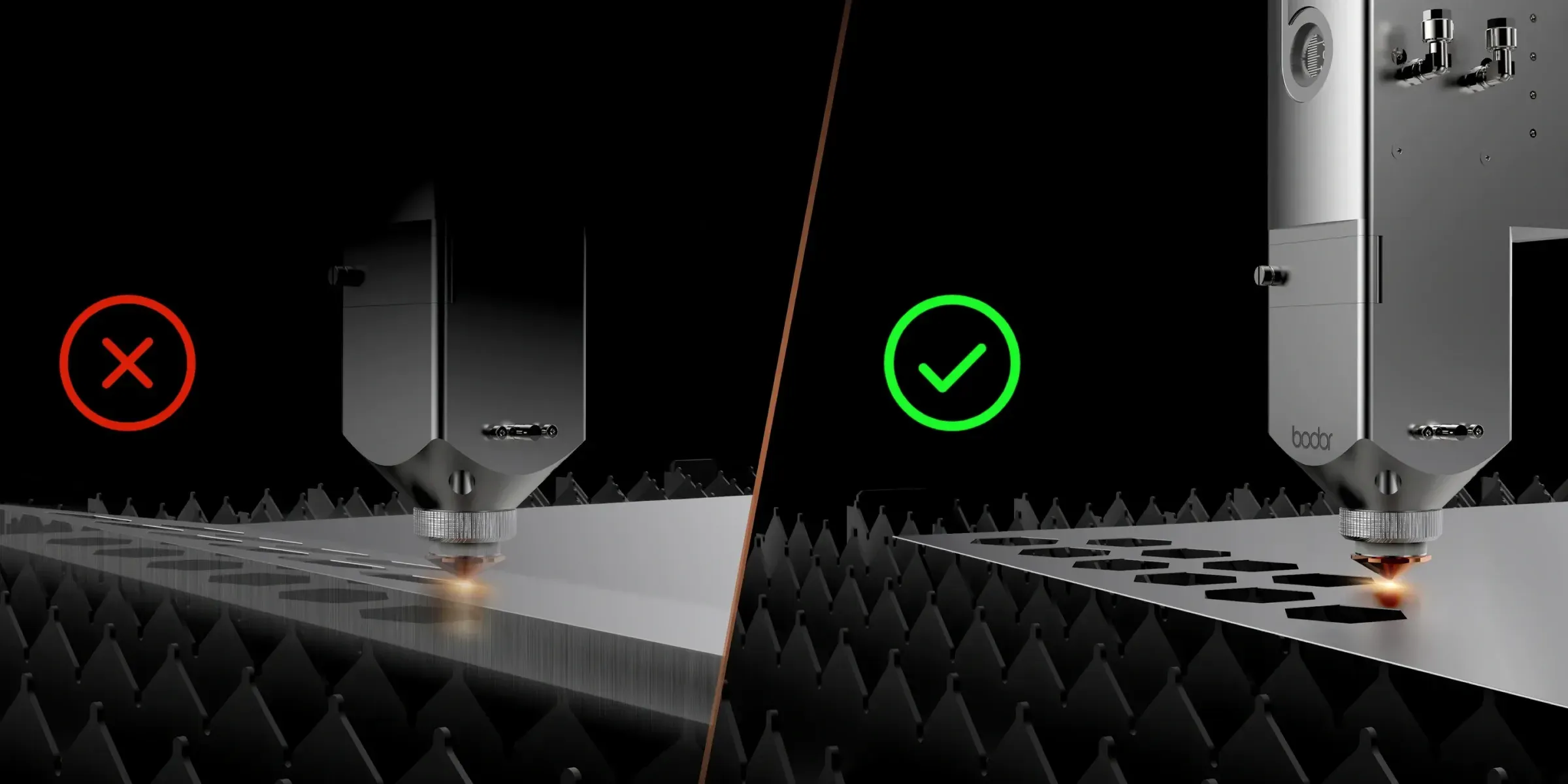

BodorGenius, Bodor’s intelligent laser head, uses sensors and algorithms to detect potential obstacles like warped edges and automatically avoids a collision. It largely ensures the stability as well as operating efficiency in the cutting process.

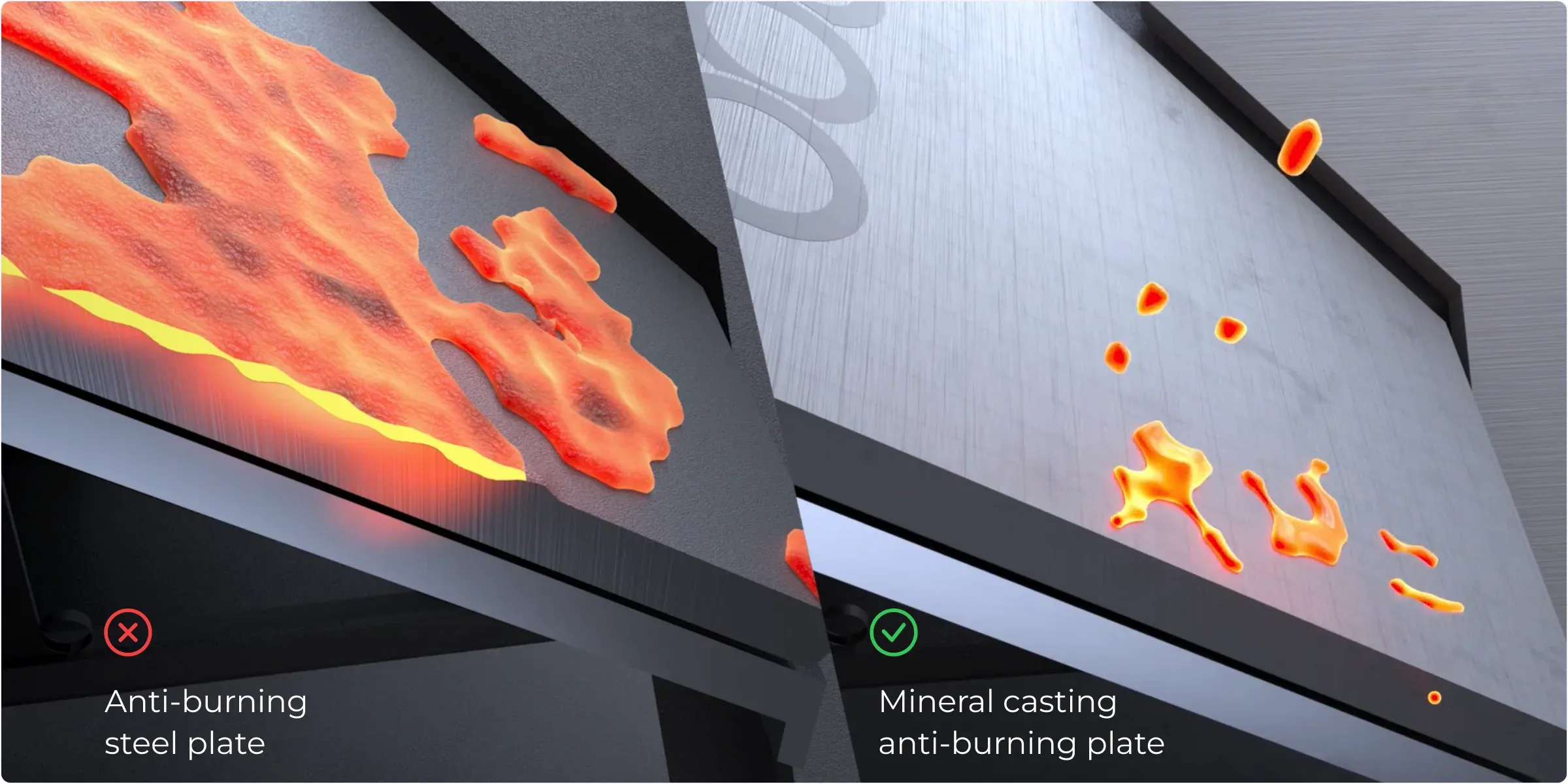

Bodor’s newly developed anti-burning plate, made by mineral casting, provides numerous advantages in slag removal, operations, modular design, fire resistance, and hardness. When in use, the plate prevents material residue and avoids heat damage to the machine bed generated by cutting, essentially lowering maintenance costs and offering better durability. Its lightweight structure also makes it easy to replace during regular maintenance.

To achieve maximum material utilization, all you need to do is uploading cutting shapes to the control system via your mobile phone. Dream series is able to automatically finish positioning as well as nesting. The higher the percentage of utilization, the better and more economical the process. Enjoy the benefits of significantly increased cost savings.

Through automatic adjustment of servo-following sensitivity, R Series prevents redundant shaking of work pieces during cutting and thus reduces failure rates.

Dream series can automatically replace nozzles without any human intervention. It also provides automated nozzle cleaning, lowering costs and saving time in operation.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!