Bodor CT Series Combo Sheet & Tube Laser Cutting Machine with the Protective Cover

The Bodor CT series can process both sheet metal and tubes, meeting a variety of processing needs. Its high efficiency and cost-effectiveness make it a powerful tool in the field of metal cutting.

Dual cutting capability: Seamlessly switch between sheet and tube cutting, offering unmatched flexibility in metal processing.

Cost-effectiveness: CT Series offers a great balance of price and performance, maximizing return on investment

Cutting with precision: Advanced technology ensures accurate and high-quality cuts.

User-friendly operation: Features like one-click processing and smart remnant layout make it easy to operate, reducing labour intensity.

All-around protection: Its comprehensive design and laser protective glass ensure safety for operators.

Set up your tasks ahead of time and let Dream series do the rest. Once the operation begins, it will automatically complete edge searching, range checking, and cutting one after another. With Dream series, you can finish batch production easily without any repetitive procedures.

BodorGenius, Bodor’s intelligent laser head, uses sensors and algorithms to detect potential obstacles like warped edges and automatically avoids a collision. It largely ensures the stability as well as operating efficiency in the cutting process.

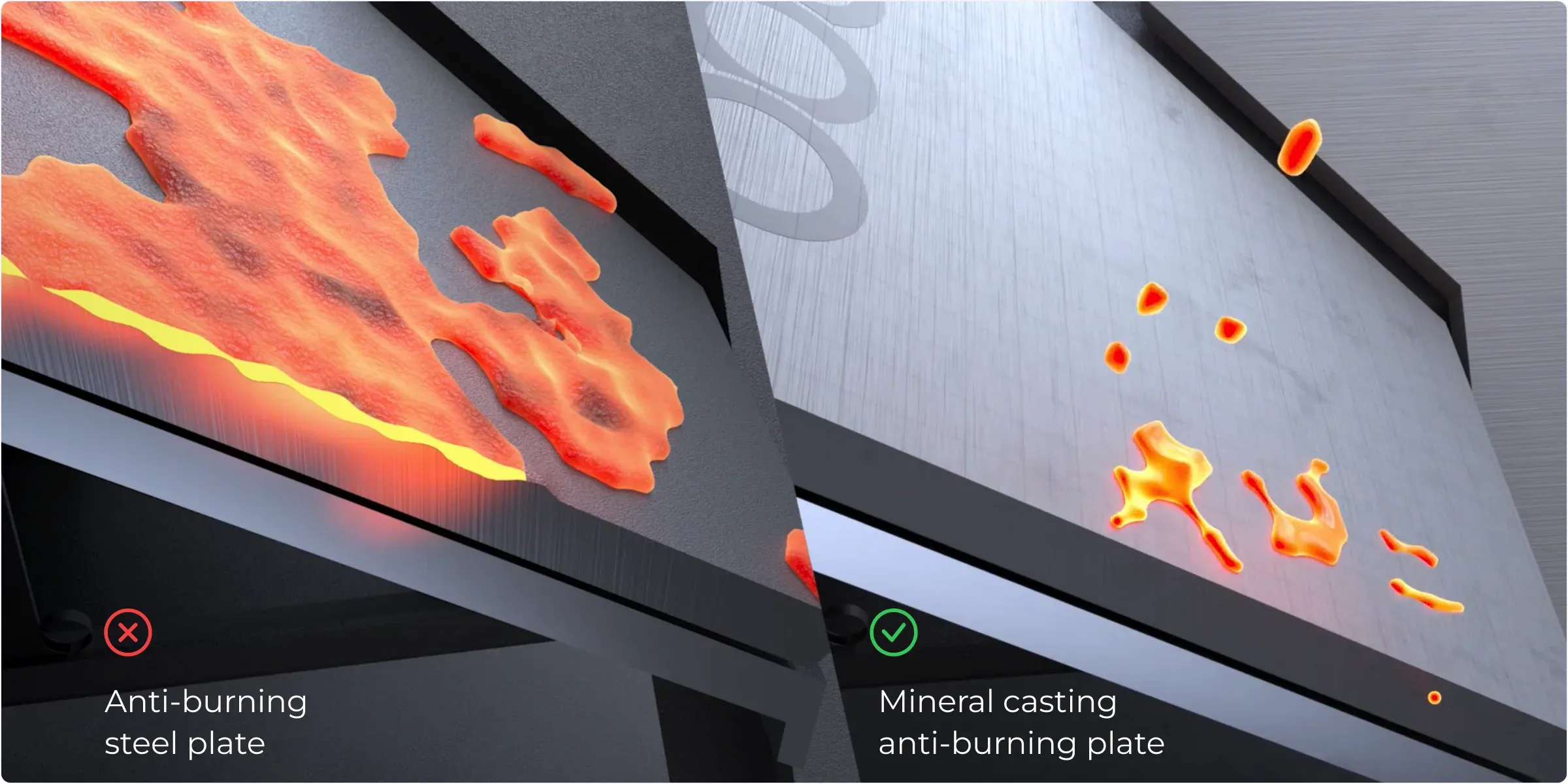

Bodor’s newly developed anti-burning plate, made by mineral casting, provides numerous advantages in slag removal, operations, modular design, fire resistance, and hardness. When in use, the plate prevents material residue and avoids heat damage to the machine bed generated by cutting, essentially lowering maintenance costs and offering better durability. Its lightweight structure also makes it easy to replace during regular maintenance.

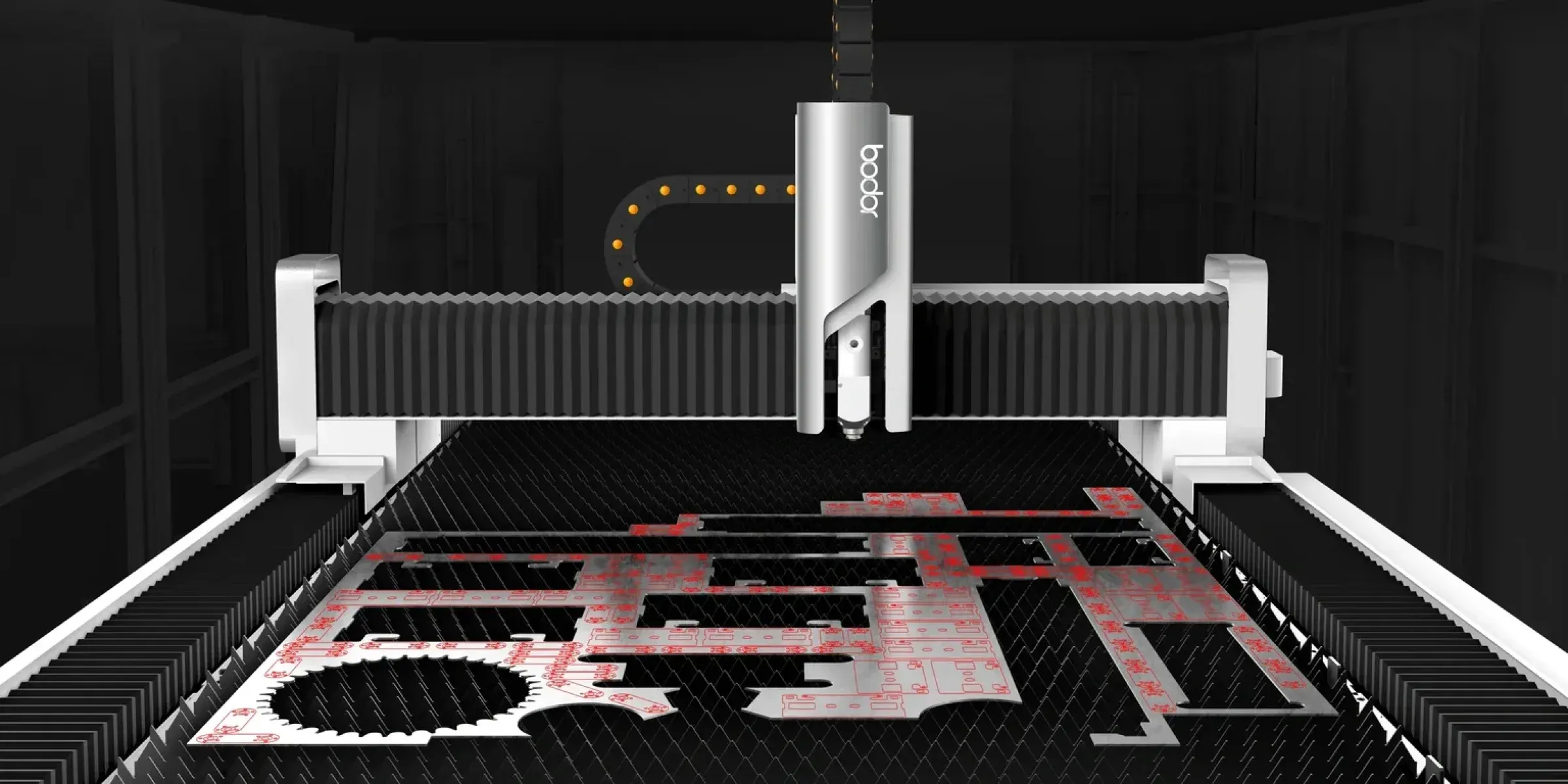

To achieve maximum material utilization, all you need to do is uploading cutting shapes to the control system via your mobile phone. Dream series is able to automatically finish positioning as well as nesting. The higher the percentage of utilization, the better and more economical the process. Enjoy the benefits of significantly increased cost savings.

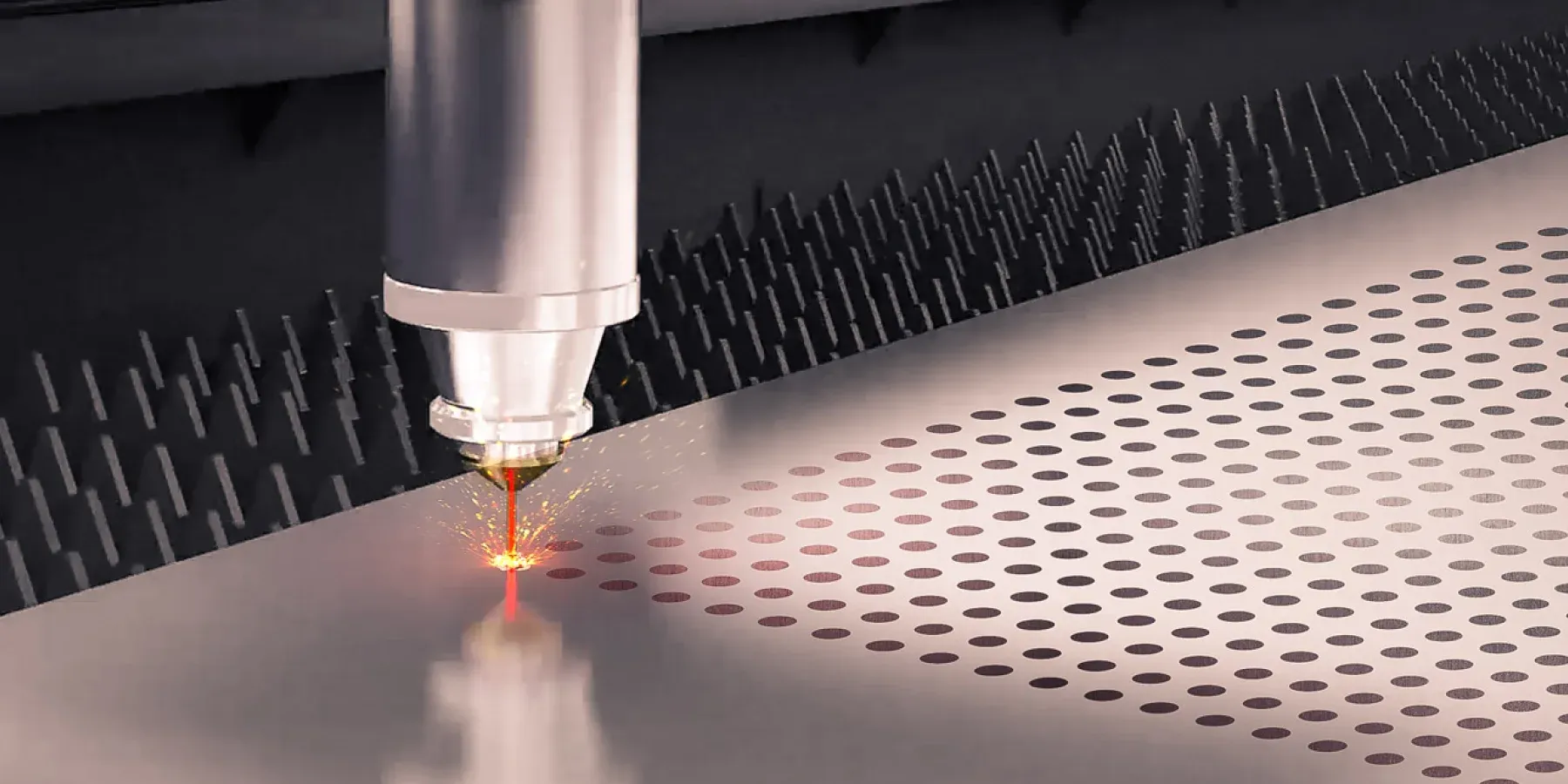

The technology offers rapid, precise piercing with a reduced amount of time. It features efficiency-monitored processes, focus adjustment, and integration with BodorGenius. This enables quick piercing in sync with the cutting head’s movement, optimizing operations for medium-thick plates without extra time or motion.

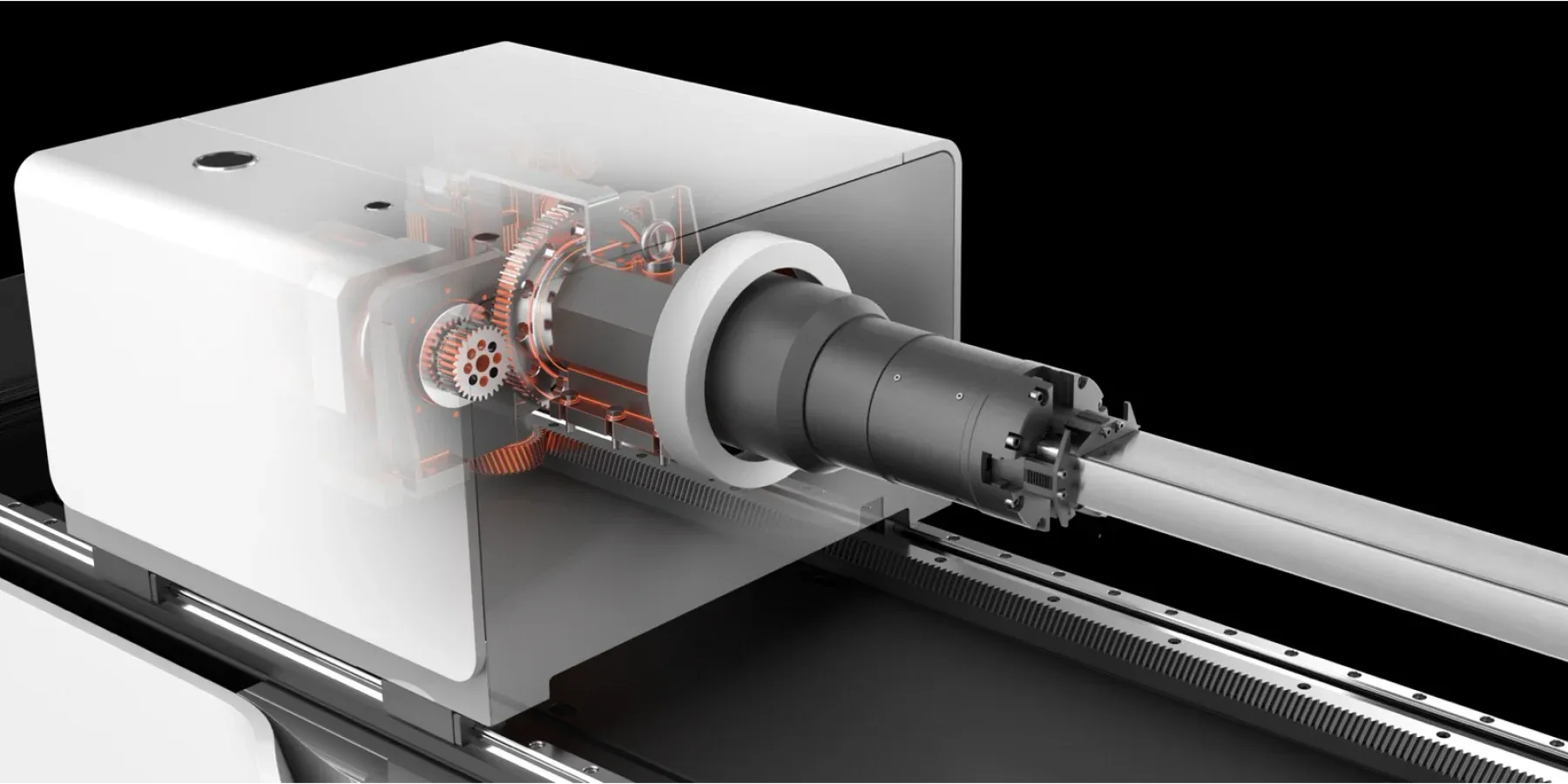

This chuck offers rapid clamping capabilities to complete the process in a mere 2 seconds, while it gear transmission structure provides stable operation and an extended service life. Its stable and strong load-bearing design makes CT series capable of precise control of speed and clamping force, ensuring no deformation and accuracy deviation for thin-walled tubes.

The nesting software for the Bodor P series has strong compatibility with Tekla, streamlining your workflow by effortlessly reading material specifications from Tekla files. It simplifies the cutting process with smart material utilization, ensuring maximum efficiency and less waste.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!