Bodor M Series Flagship Fiber Laser Metal Tube Cutting Machine

Maximum capacity, for all tube cutting demands.

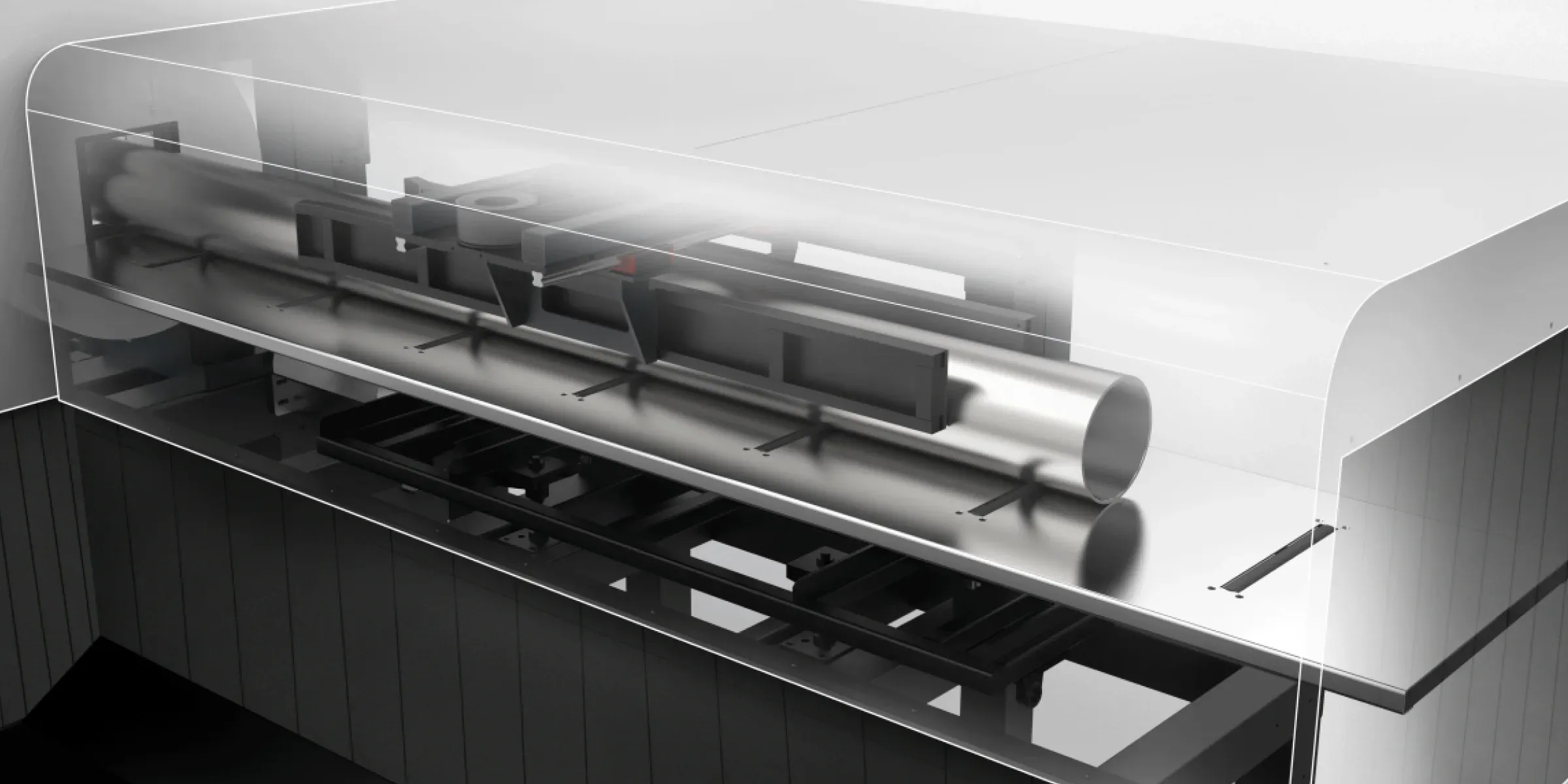

Extra large cutting range: The M Series adopts a square-round structure chuck, which allows it to cut the maximum round tube diameter and the maximum square tube side length, providing users with more processing options.

0 Excess Material Processing, Waste Reduction: Minimize manufacturing waste from the source. During operations, the M Series will help you utilize every piece of material to the largest extent possible, reducing waste and improving cost-effectiveness.

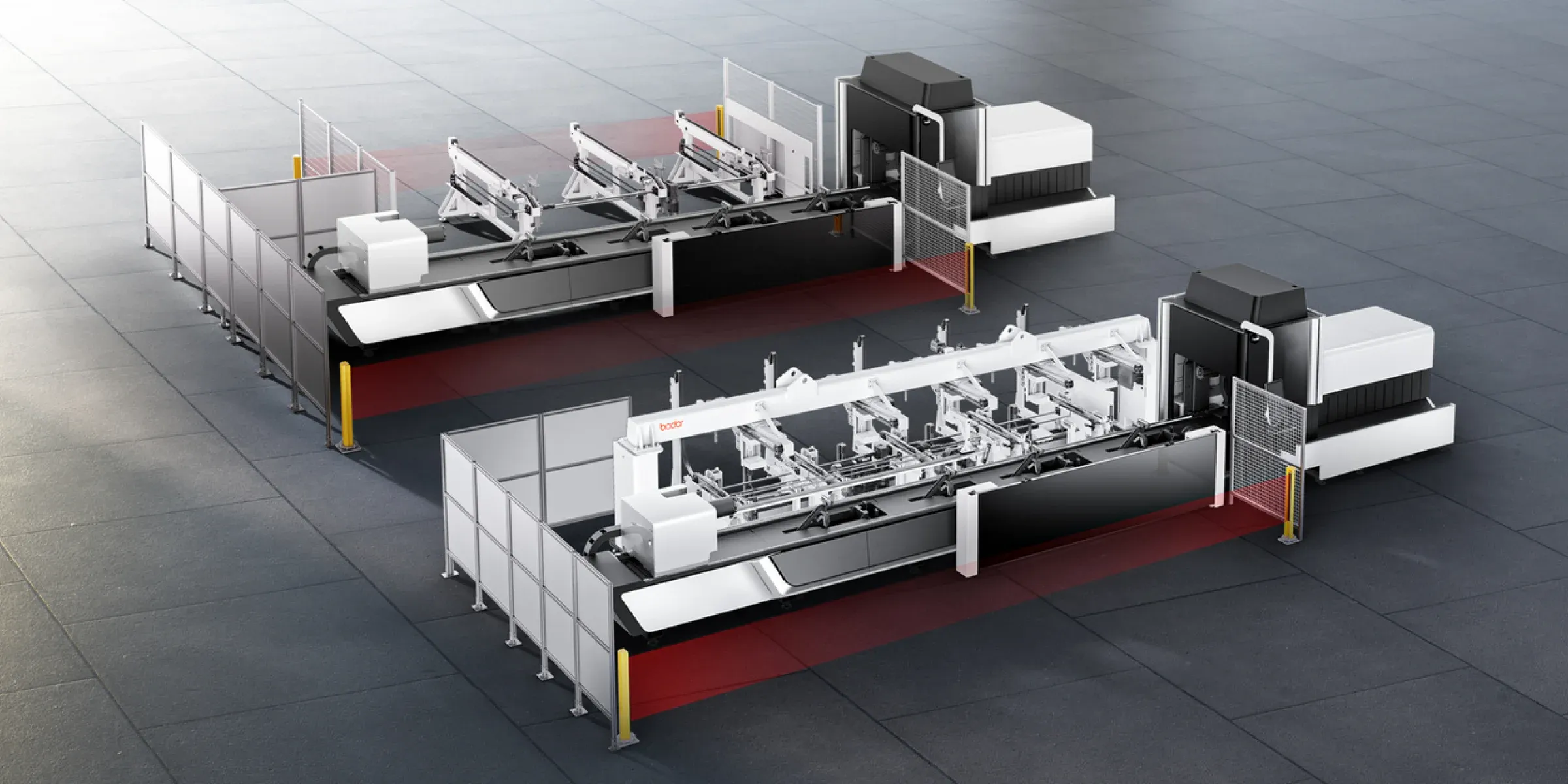

Increased flexibility: The M Series’s four chucks can be adapted to different processing scenarios. By intelligently switching between the heavy tube processing and high-efficiency modes, the machine empowers you to tackle diverse cutting tasks with ease.

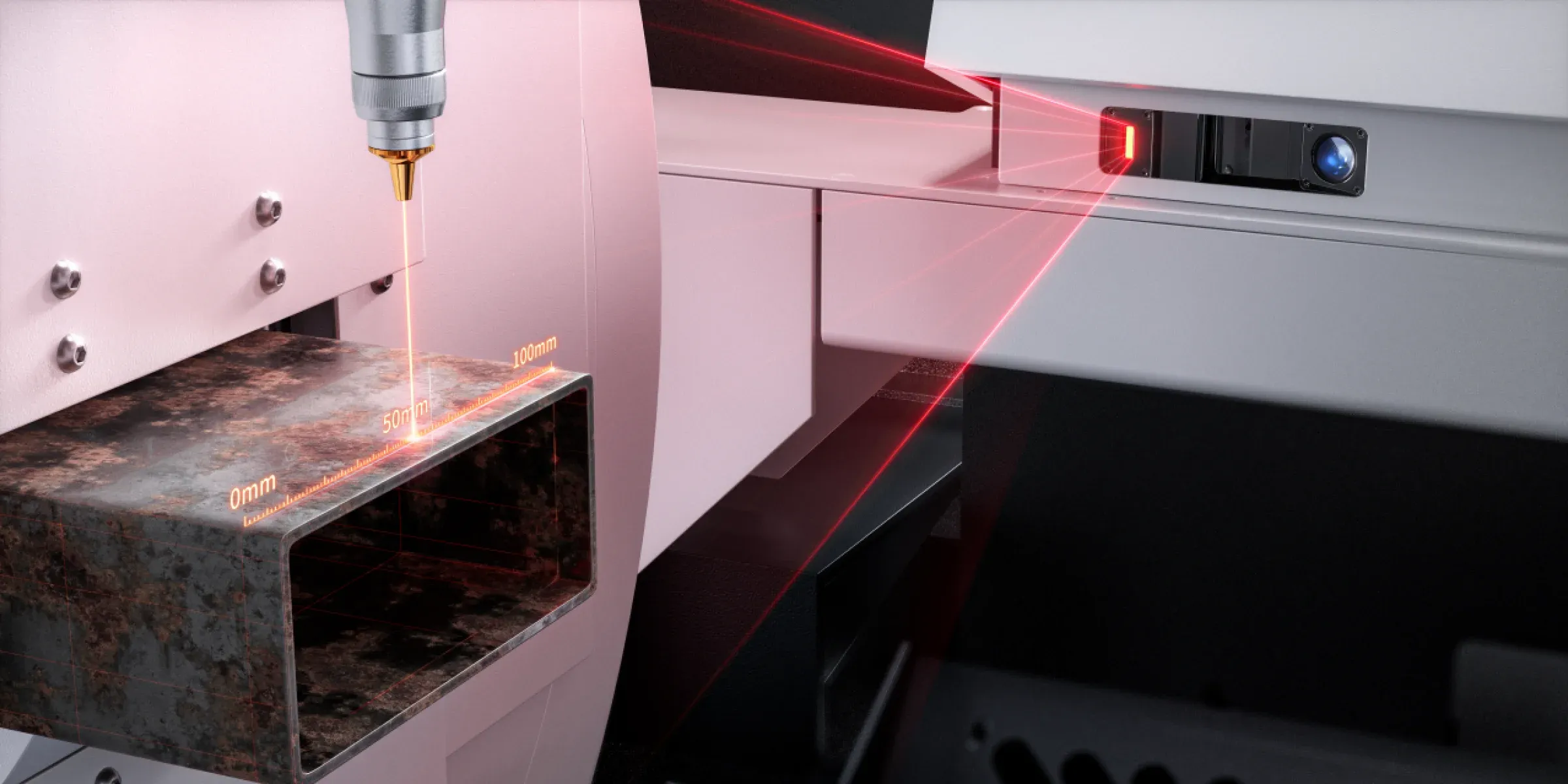

Unlike traditional capacitor centering, T series finishes centering in just 0.26 seconds, doubling its cutting precision. There’s no downtime as the process can start right away. This technique is not affected by external situations like environments, temperatures, light, or tube conditions, stabilizing operations with high adaptability.

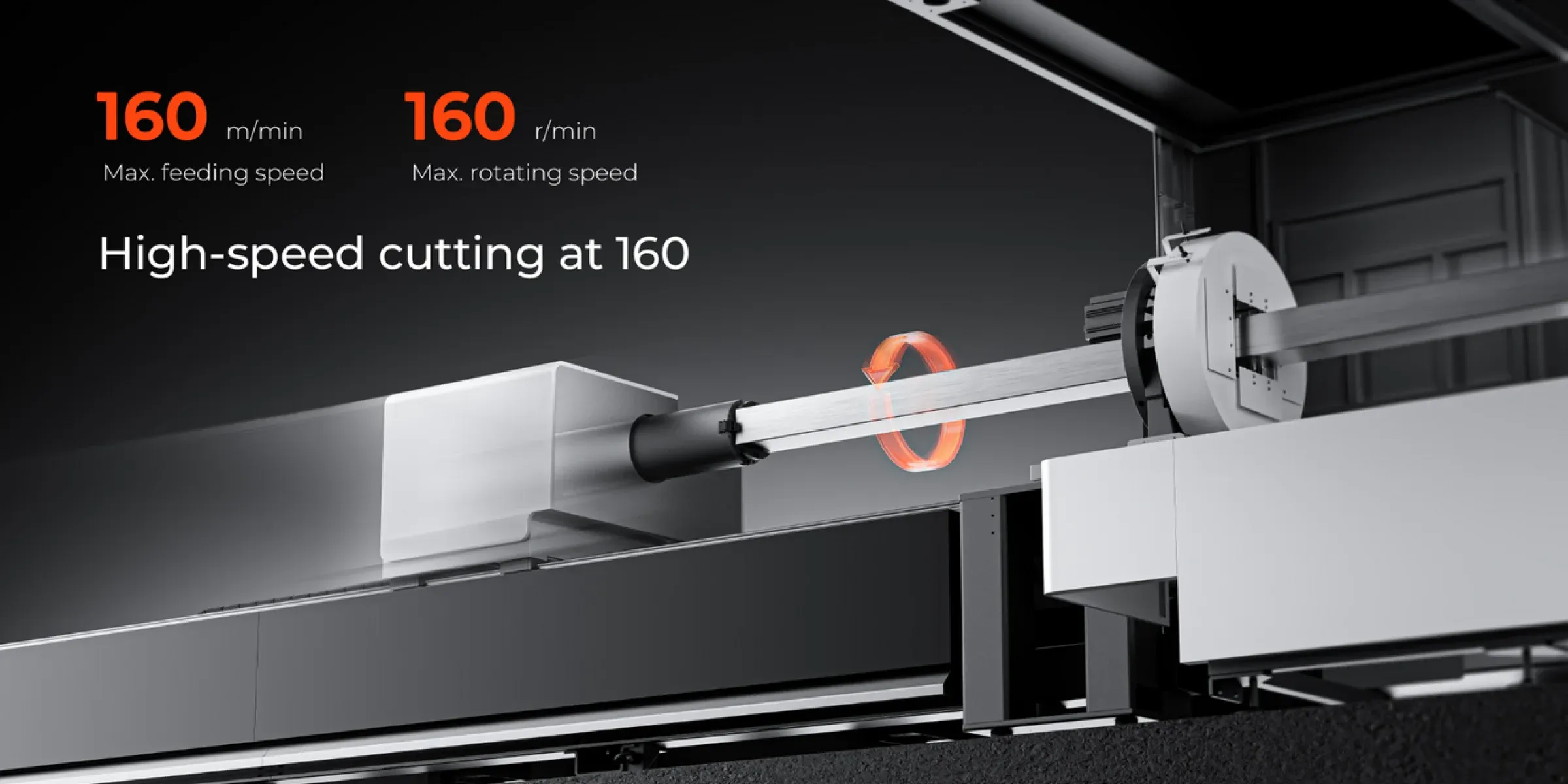

With a feeding speed up to 160m/min and a rotating speed up to 160r/min, T series improves processing efficiency by 20% in comparison to that of the industry standard.

With Bodor’s cutting process database, T series’ control system is able to intelligently select and match the best cutting parameters (e.g. feeding speed, chuck rotating speed, and clamping force) based on the types of the tubes, ensuring the best operating performance at all times. It as well substantially cuts down labor costs since it requires zero manual intervention.

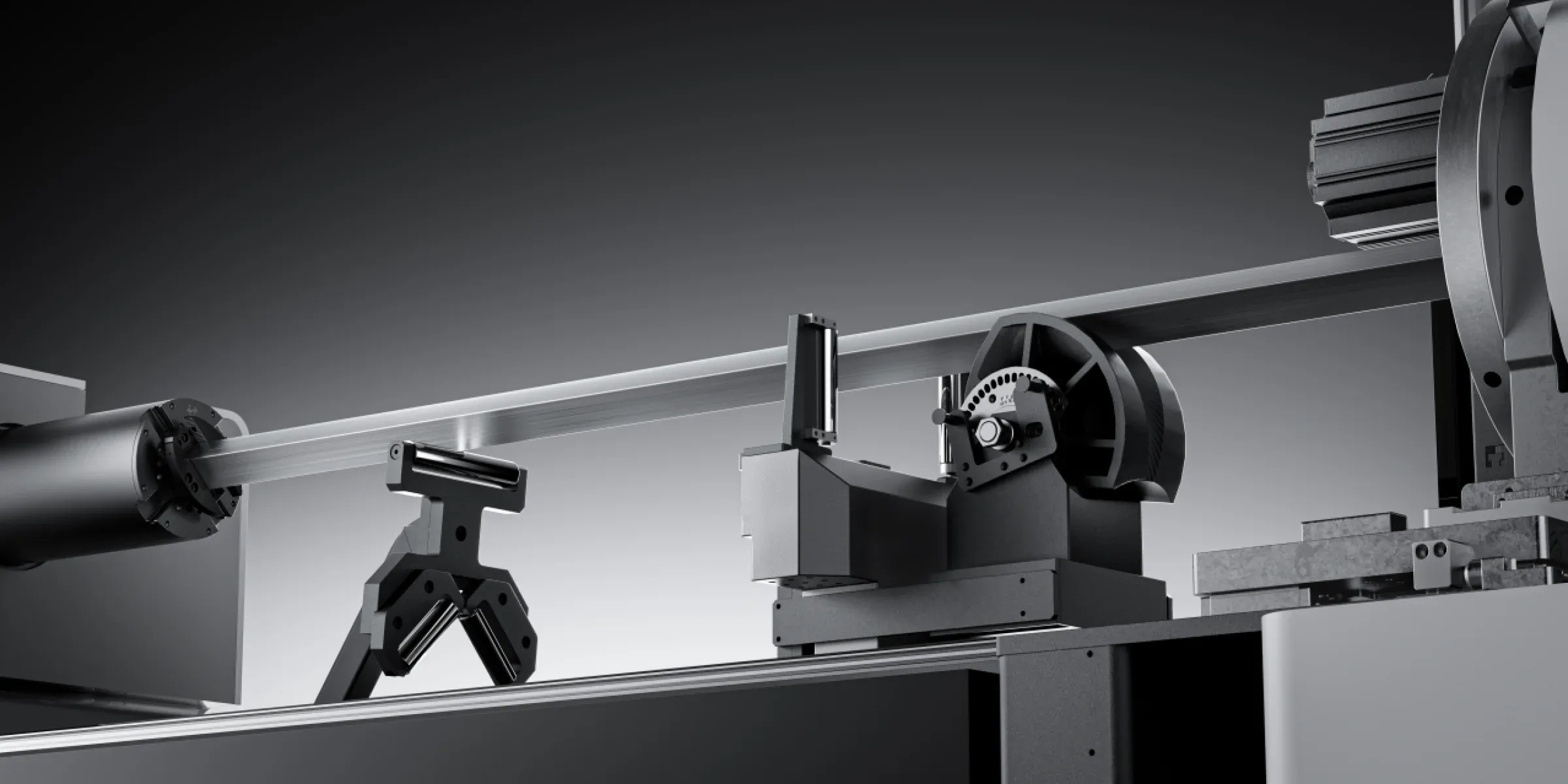

The full coverage support of the U-shaped combined roller ensures tube stability even during high-speed rotating (up to 160r/min) and greatly improves cutting precision.

The servomechanism of T series guarantees all machinery procedures work synchronously. The new servo-flipping plate has adaptive motions to facilitate the unloading process. While preventing redundant shaking or moving of the work piece, the plate is able to automatically categorize work pieces and remnant into different piles, thus lowering labor costs.

T series machines allow users to manufacture standard and customized-shaped steel tubes for their application needs. They have the capability to cut tubing in square, rectangular, flat sided oval, elliptical and many other custom shapes in a variety of metals.

T-Series can be paired with the automatic loading system T-Trans and/or the auxiliary loading device T-Loader. You can choose either one of them based on your production needs.

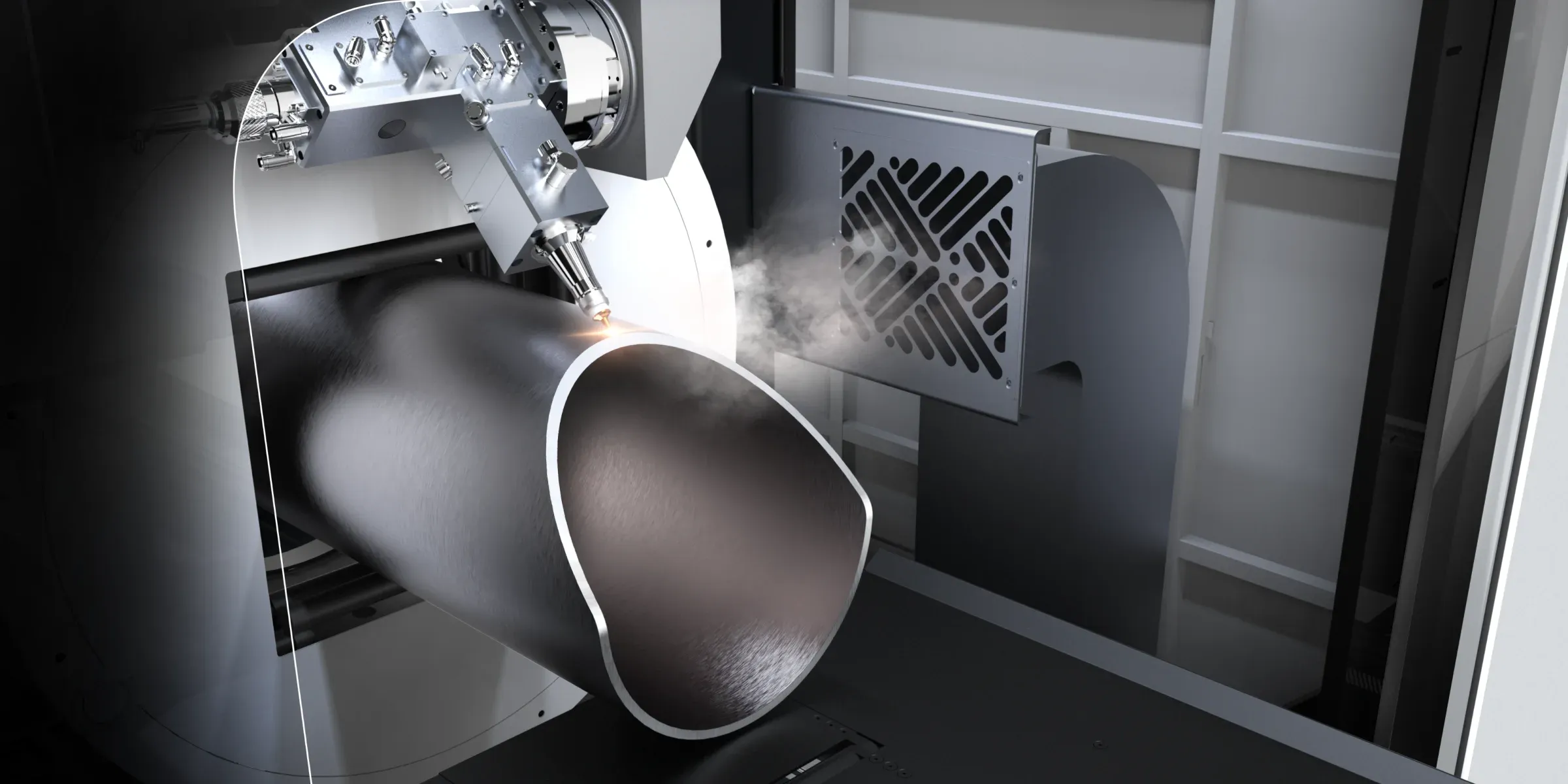

The bevel cutting option of T series enables the production of high-precision bevel cuts in +/- 45 degrees, optimizing subsequent assembly procedures and welding performance while lowering production costs.

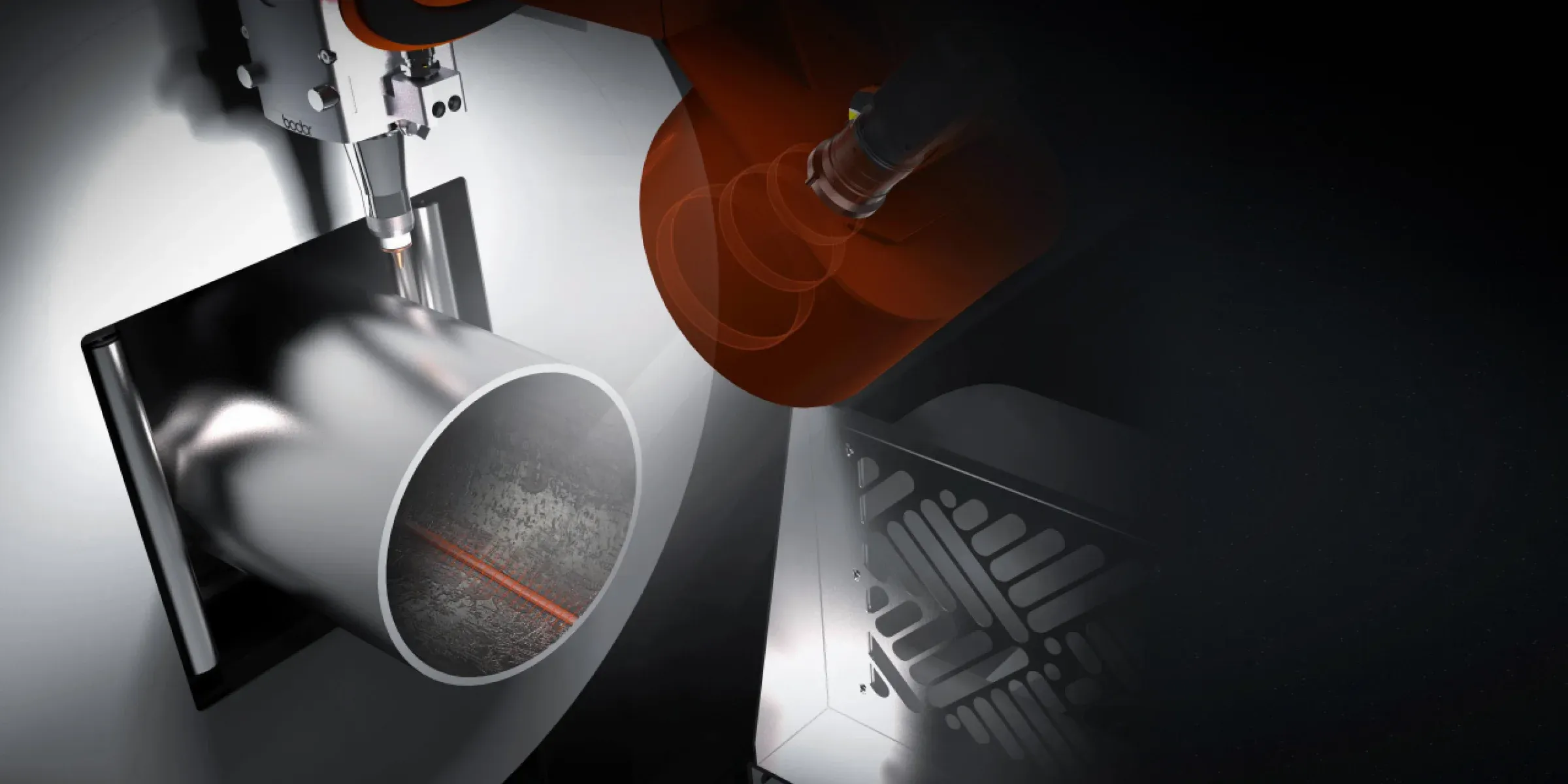

With a simple camera set-up, T series can quickly detect weld seams located on the inside. This option is applicable to a variety shapes of tubes. It is particularly helpful to manufacturers who would like to avoid weld seams during laser cutting.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!