Bodor P Series all-around sheet metal fiber laser cutting machine

The Bodor P Series sheet metal laser cutting machines are the epitome of cutting-edge laser technology and outstanding performance. Craftsmanship, automation features, and safety measures have been finely tuned in our P Series to provide an unparalleled cutting experience.

Supercharged productivity: Bodor P Series laser cutting machines are engineered to turbocharge your productivity. Say goodbye to tedious operations – just a single click starts automated cutting, saving you valuable time and enhancing efficiency.

Resource efficiency: Our commitment to minimizing resource waste is unwavering. The P Series is designed for efficient use of materials, gases, and electricity, reducing costs and environmental impact while maximizing value.

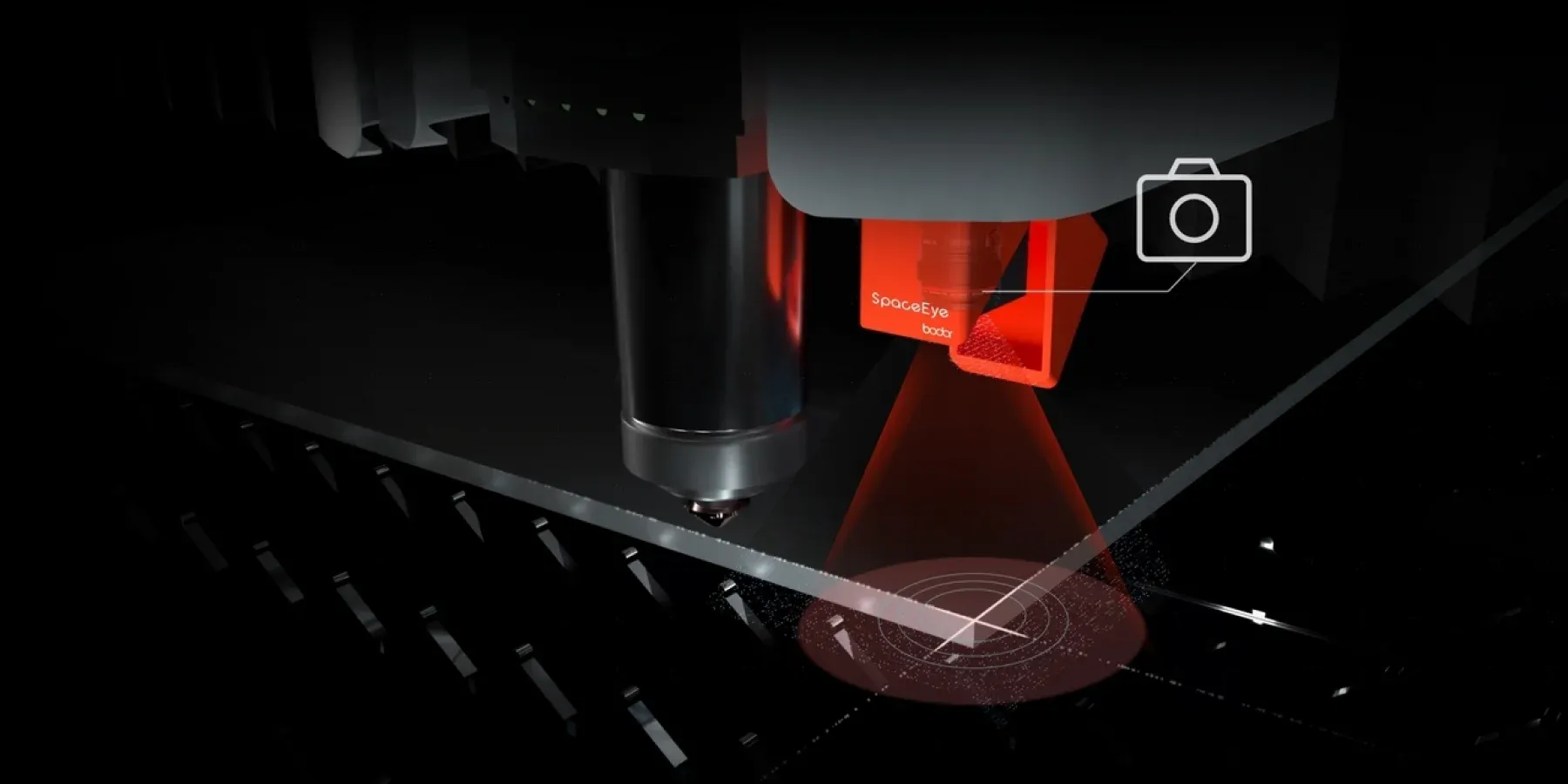

User-friendly operation: Simplifying operations is our forte. Our one-second edge finding technology eliminates the hassle of manually locating cutting positions. An intuitive touchscreen interface makes operation straightforward, requiring minimal training for seamless integration.

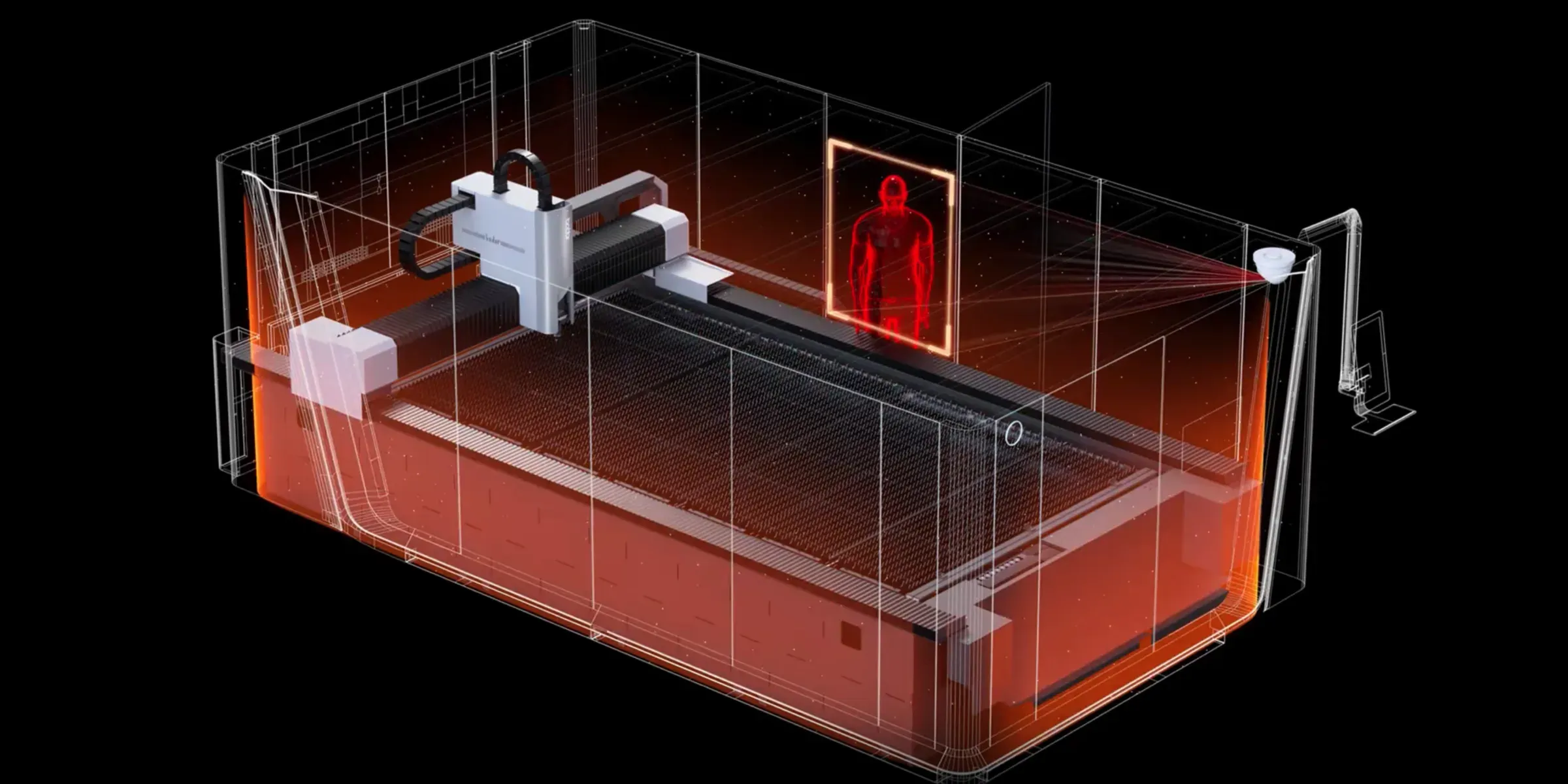

Safety first: Safety and maintainability are paramount. Equipped with visual collision detection and active collision avoidance functions, our equipment ensures operational safety. Automatic cleaning and intelligent air pressure control extend equipment lifespan and reduce maintenance costs.

Top-notch cutting quality: We are committed to delivering exceptional cutting quality every time. This translates to more accurate products, reduced waste, and happier customers. High-speed cutting processes provide faster cutting speeds for increased production efficiency.

Our intelligent visual collision avoidance technology is able to detect motions and signal warnings to prevent possible collisions. You can select either high or low sensitivity modes to ensure operator’s safety, no longer worrying about satefy issues.

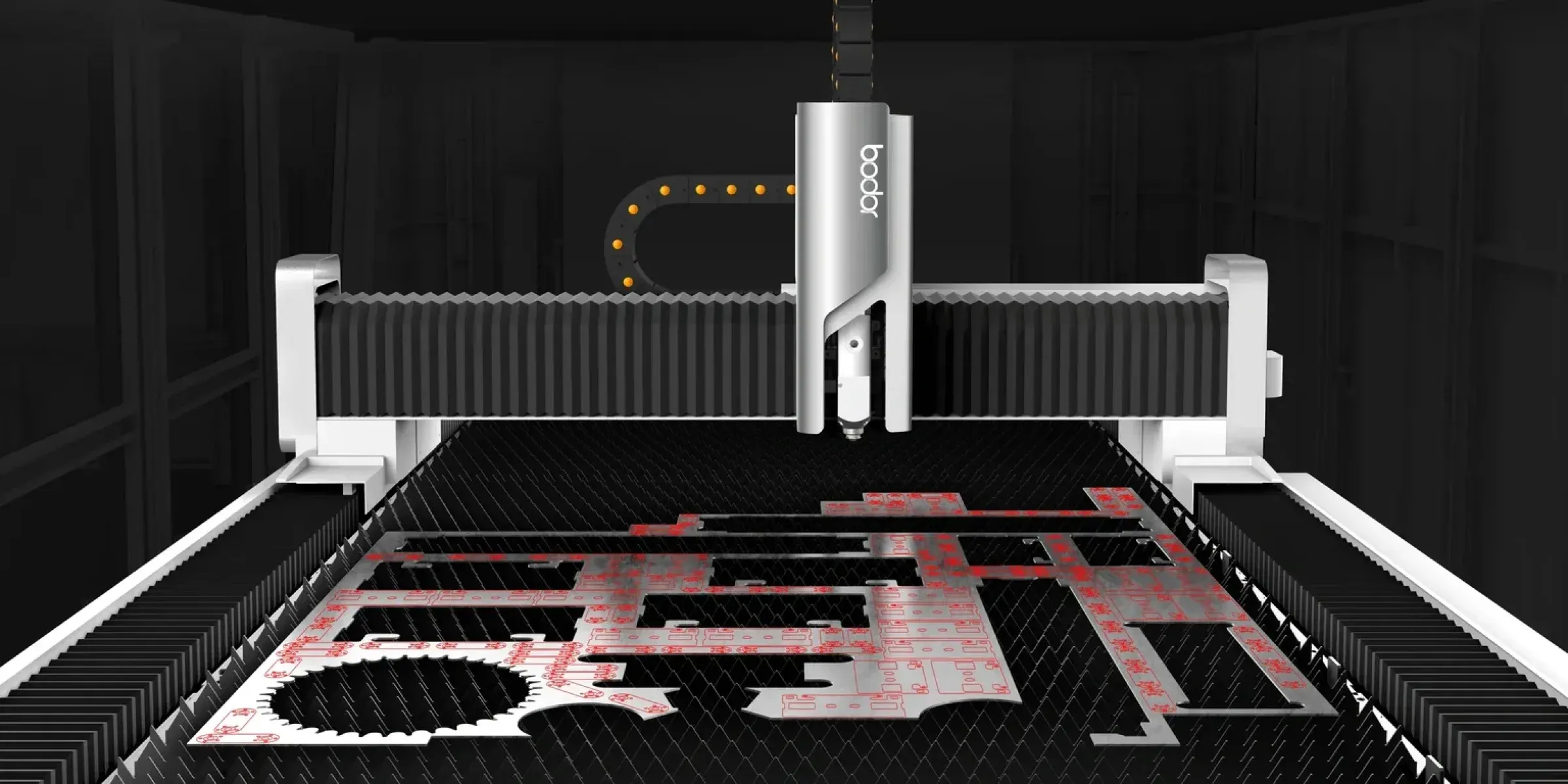

The nesting software for the Bodor P series has strong compatibility with Tekla, streamlining your workflow by effortlessly reading material specifications from Tekla files. It simplifies the cutting process with smart material utilization, ensuring maximum efficiency and less waste.

BodorGenius, Bodor’s intelligent laser head, uses sensors and algorithms to detect potential obstacles like warped edges and automatically avoids a collision. It largely ensures the stability as well as operating efficiency in the cutting process.

To achieve maximum material utilization, all you need to do is uploading cutting shapes to the control system via your mobile phone. Dream series is able to automatically finish positioning as well as nesting. The higher the percentage of utilization, the better and more economical the process. Enjoy the benefits of significantly increased cost savings.

The bevel cutting option of P series enables the production of high-precision bevel cuts in +/- 45 degrees, optimizing subsequent assembly procedures and welding performance while lowering production. (Available cuts include A-cut bevel, V-cut bevel, Top Y-cut bevel, X-cut bevel, and K-cut bevel)

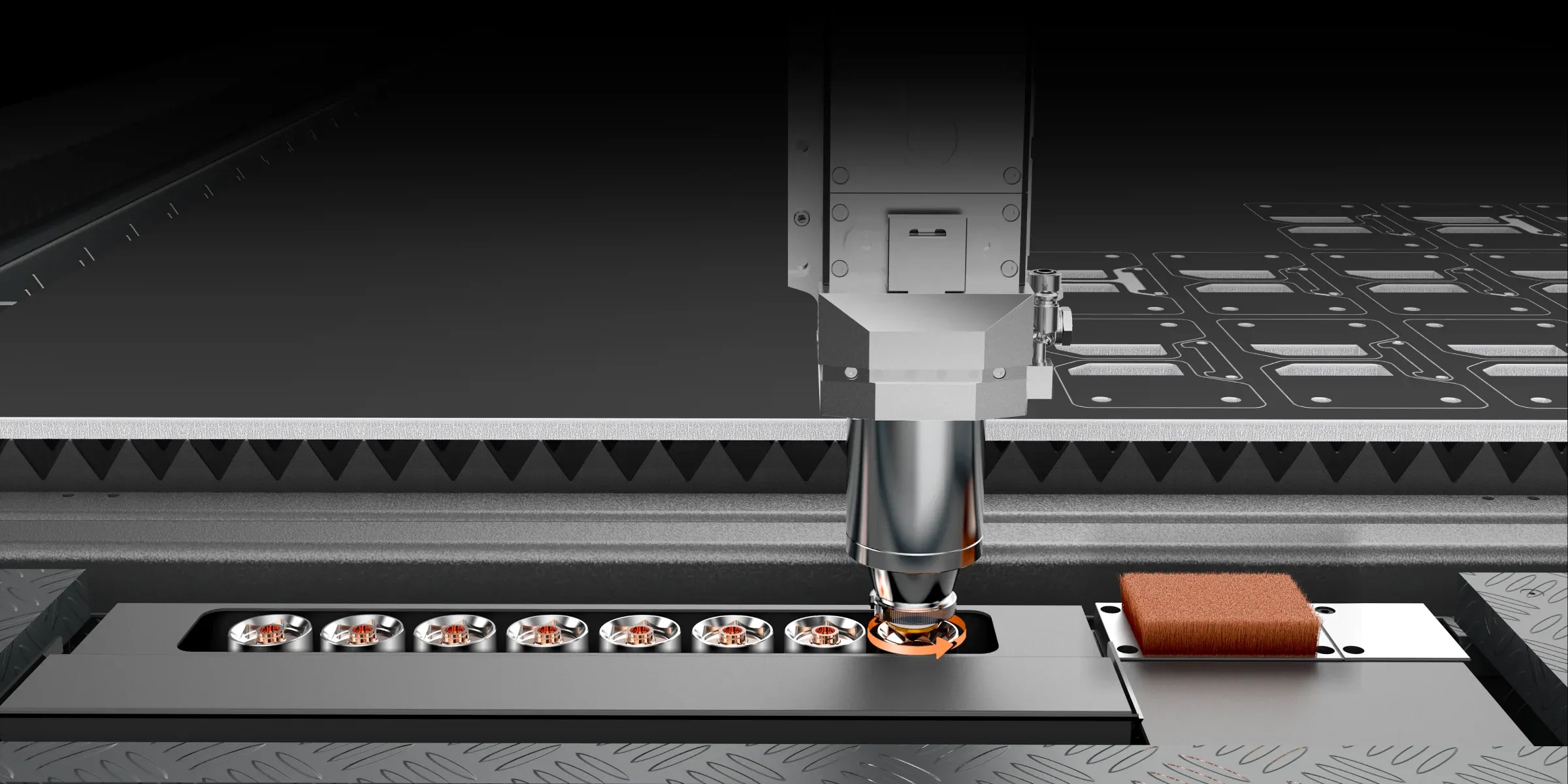

Dream series can automatically replace nozzles without any human intervention. It also provides automated nozzle cleaning, lowering costs and saving time in operation.

One-second edge finding ensures rapid material positioning and focus calibration. With an optical camera, the system automatically identifies the material’s position and locates its origin and angular offset within 1 second. This visual and algorithmic innovation simplifies operating procedures and completes cutting, recognition, and focus compensation in one go, largely reducing working time.

Set up your tasks ahead of time and let Peries do the rest. Once the operation begins, it will automatically complete edge searching, range checking, and cutting one after another. With Dream series, you can finish batch production easily without any repetitive procedures.

Maximize your metal cutting with Logi Laser Engineering, your Bodor laser specialist. We provide expert sales, service, repair, and unmatched support – all at competitive prices. Our commitment to quality and customer satisfaction ensures your Bodor laser delivers peak performance.

Get updates on new products and stay ahead of the curve!