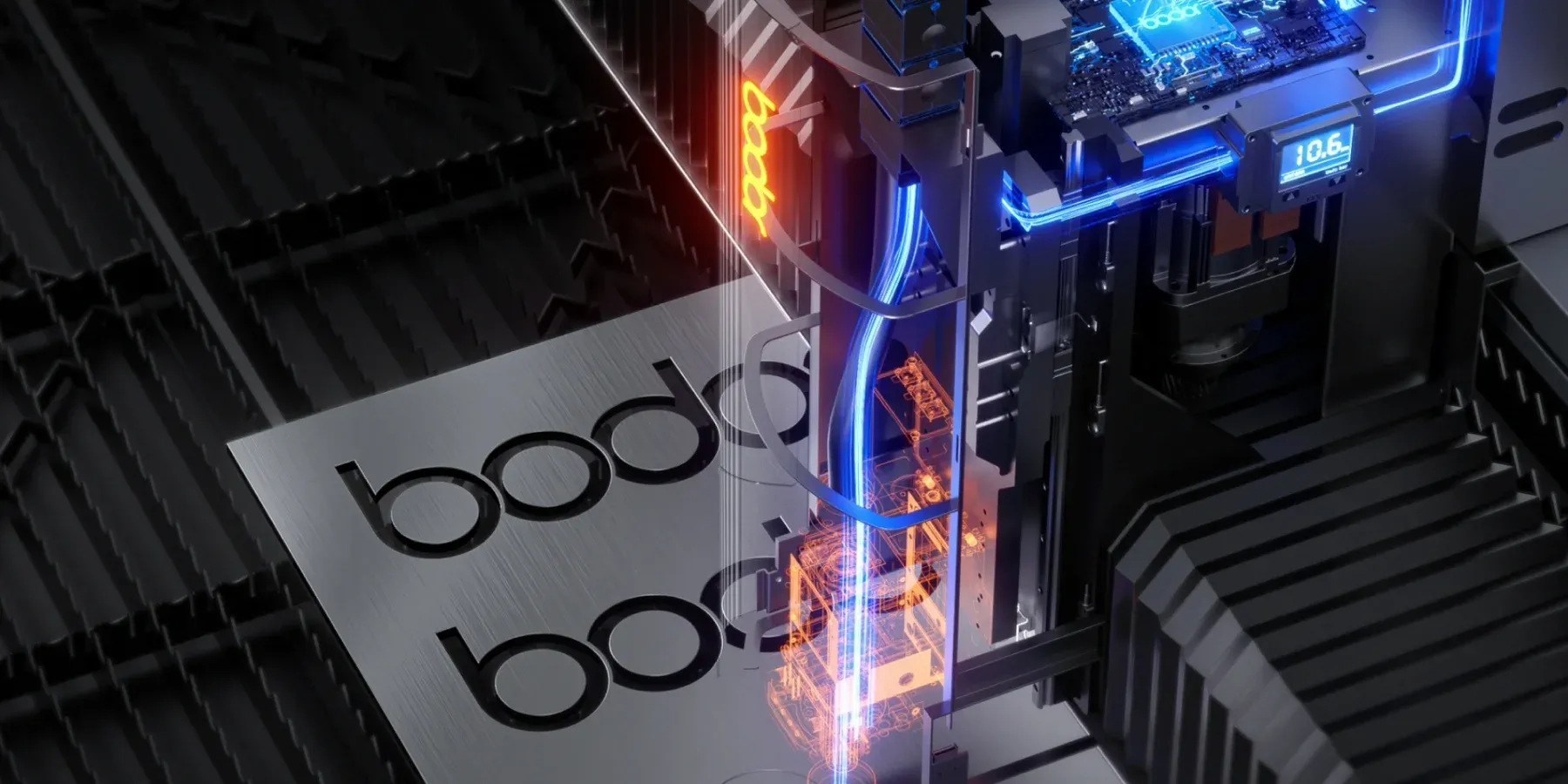

Fibre laser cutting has revolutionised metal fabrication, prised for its unmatched precision, speed, and clean cuts. But a crucial consideration for any metalworker is cutting thickness: how much metal can a fibre laser handle? Let’s delve into the technical aspects that determine a fibre laser’s cutting capacity.

Power Dynamics: The Engine of Fibre Laser Cutting

The cutting thickness of a fibre laser cutter hinges primarily on its laser power. This power, measured in watts (W) or kilowatts (kW), dictates the intensity of the laser beam and its ability to melt or vaporise metal. Here’s the breakdown:

- Higher Power, Greater Depth: Higher laser power output translates to a more intense beam, capable of penetrating deeper into thicker metals. Industrial fibre lasers can range from a few kilowatts (kW) to well above 40 kW, enabling them to tackle a wider range of thicknesses.

- Material Matters: The type of metal being cut also plays a significant role. Metals with lower melting points, like mild steel, are generally easier to cut through at a given laser power compared to metals with higher melting points, like titanium.

Cutting Thickness Ranges: A Practical Perspective

While the exact cutting thickness capabilities vary depending on the specific fibre laser model and material being cut, here’s a general guideline:

- Thin Metals (up to 10mm): Lower-powered fibre lasers (in the 1-5 – 3 kW range) excel at cutting thin sheets of metal, ideal for applications requiring intricate details and high precision.

- Medium Thickness Metals (10 mm – 40 mm): Mid-range fibre lasers (6-12 kW) offer a good balance between cutting thickness and processing speed, making them suitable for a wider variety of metal fabrication tasks.

- Thick Metals (40 mm and above): High-powered fibre lasers (22 kW and above) are the workhorses for cutting thick metal plates. These lasers deliver the necessary power to pierce through substantial material thicknesses.

Beyond Power: Factors Influencing Cutting Thickness

Laser power is not the sole determinant of cutting thickness. Other factors also come into play:

- Assist Gas: The type of assist gas used (often oxygen for mild steel, nitrogen for aluminium and stainless steel) can influence cutting efficiency and achievable thickness.

- Cutting Speed: Slower cutting speeds allow for deeper penetration and thicker cuts, while faster speeds prioritise throughput for thinner materials.

- Focus Quality: A well-focused laser beam concentrates its power for deeper penetration and thicker cuts.

Conclusion:

Fibre laser cutters offer a remarkable range of cutting thicknesses, from delicate sheets to substantial metal plates. By understanding the interplay between laser power, material properties, and process parameters, metal fabrication professionals can leverage fibre laser technology to its full potential.