Fibre laser cutting has emerged as a dominant force in metal fabrication, lauded for its exceptional precision, speed, and clean cuts. But a crucial question lingers: what metals can this technology conquer? Let’s delve into the technical aspects that govern a fibre laser’s material compatibility.

The Power of Light-Matter Interaction:

Fibre laser cutting relies on the interaction of a highly focused laser beam with the metal surface. This interaction can manifest in two primary ways, depending on the desired outcome and material properties:

• Melting and Piercing: For thicker metals, and predominantly steel, the laser beam melts the material at the focal point. An assist gas, often oxygen, accelerates this melting to create a clean kerf (cut width). The molten metal is then blown away by the pressure gas jet (Usually around 1 Bar), allowing the laser to pierce through the material.

• Vaporization and Shearing: For thinner metals, the intense heat from the laser directly vaporizes the metal at the focal point. An assist gas, often nitrogen or oxygen, in this case, serves to remove the vaporized material and keep the kerf clean. Additionally, the pressure from the gas jet can also play a role in shearing the molten metal at the edges, contributing to a sharper cut.

Metal Considerations for Fibre Laser Cutting:

Several factors influence a metal’s suitability for fibre laser cutting:

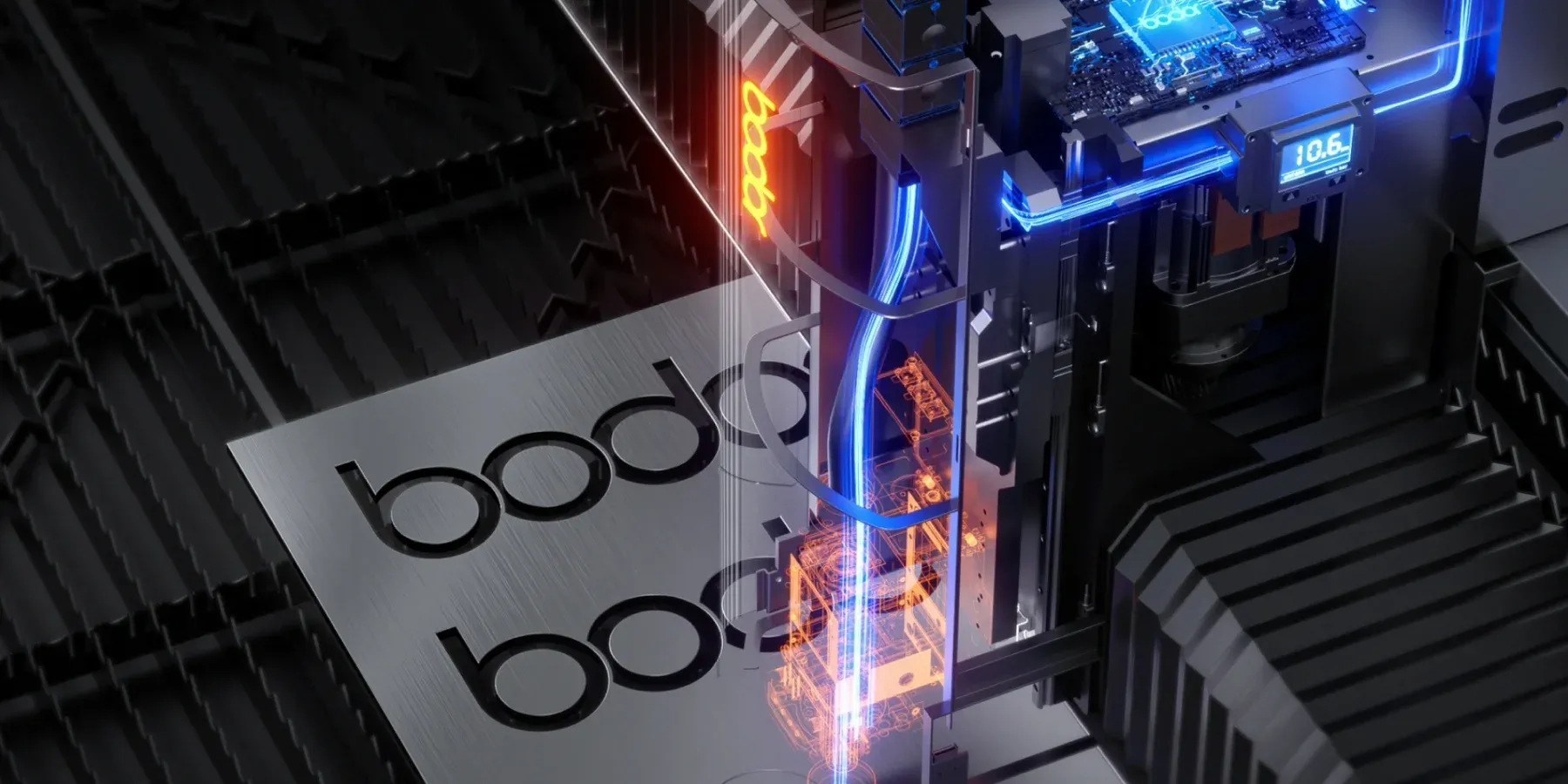

• Reflectivity: Metals with high reflectivity, like aluminium, brass and copper, can deflect the laser beam, reducing cutting efficiency. However, modern fibre lasers employ shorter wavelengths (around 1064nm) that are less susceptible to reflection compared to CO2 lasers (around 10,600nm). Especially when a Bodor Scan cutting head is used.

• Thermal Conductivity: Metals with high thermal conductivity, like aluminium, can rapidly dissipate heat away from the focal point, making them slightly more challenging to cut cleanly. However, proper laser power adjustments and assist gas selection mitigate this effect.

• Melt Point and Vaporisation Point: The melting point and vaporisation point of the metal determine the laser power required for effective cutting. Fibre lasers offer a wide range of power outputs, enabling them to handle metals with varying melting and vaporization points and can cut metals up 100mm thick, when using a high power laser.

Conquer a Spectrum of Metals:

By considering these technical aspects, fibre laser cutters demonstrate exceptional versatility in handling a broad spectrum of metals, including:

• Ferrous Metals: Mild steel, stainless steel, high-strength steel, tool steel

• Non-Ferrous Metals: Aluminium, copper, brass, titanium, magnesium

Conclusion:

Fibre laser cutting technology boasts remarkable material versatility. Its ability to handle a wide range of metals, coupled with its superior precision, speed, and clean cuts, solidifies its position as a leading force in modern metal fabrication.