Introduction

In the world of metal fabrication, the phrase “time is money” isn’t just a cliche – it’s a hard-edged reality. The faster and more accurately you can cut and shape metal, the more efficiently your business operates, and the healthier your bottom line. That’s where fibre laser cutting machines are reshaping the industry.

Sure, you’ve probably heard all the buzzwords: increased speed, precision, reduced costs… and they’re all true. But the real question, especially as a small to medium-sized business owner, is a simple yet profound one: “Is a metal fibre laser cutting machine right for me?”

Let’s be honest, these machines represent a significant investment. It’s not a decision to rush into. Instead, it’s about weighing the potential benefits against your business’s specific needs and goals. Think of it as an opportunity to reimagine your fabrication processes from the ground up.

In this article, we’ll delve into the top five reasons why a fibre laser cutting machine might be the transformative piece of equipment that gives your business a significant edge. We’ll break down the technical jargon and address the crucial factors to consider when making this important decision.

Section 1: Precision and Accuracy

Metal fabrication often demands a level of precision that pushes traditional cutting methods to their limits. In industries like aerospace, medical devices, or intricate architectural work, even the slightest deviation can have critical consequences. Fibre laser cutting machines set a new standard in precision, unlocking capabilities that can elevate the quality of your work and expand your business potential.

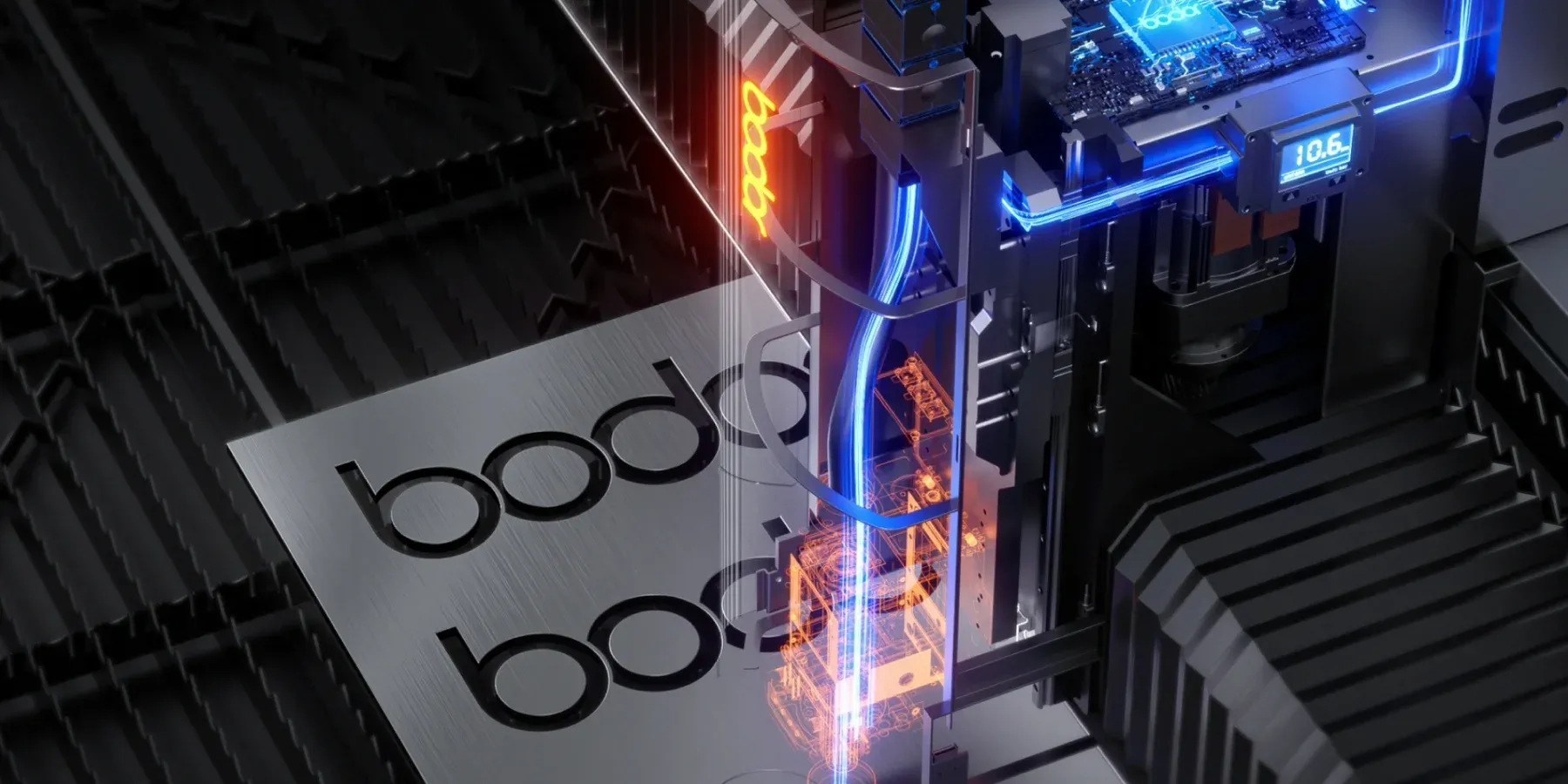

Unmatched Cut Quality

The secret to the precision of fibre lasers lies in their incredibly focused beam of light. This concentrated energy acts like a surgical scalpel for metal, producing remarkably clean cuts with minimal burrs and virtually no heat distortion. The result? Reduced secondary operations like grinding or deburring, saving you precious time and ensuring a superior finish on your products.

Tolerance Control

In manufacturing, meeting tight tolerances is often the difference between a satisfied customer and a costly rework. Fibre laser cutting machines excel in this area, consistently achieving tolerances within fractions of a millimetre. This level of accuracy ensures that your components fit together flawlessly, eliminating guesswork and boosting your reputation for delivering exceptional results.

The Importance of Precision

To fully appreciate the impact of fibre laser precision, consider the broader implications for your business processes. When you can consistently produce accurate parts, it streamlines downstream operations like assembly and welding, saving time and minimizing material waste. This translates into faster turnaround times, increased customer satisfaction, and the ability to confidently tackle even the most demanding projects.

To learn more about how fibre lasers are revolutionising modern manufacturing, check out this insightful article on Rise Tek Machinery’s website: The Cutting-Edge Impact of Fibre Laser Machines on Modern Industrial Manufacturing Processes: https://risetekmachinery.com/the-cutting-edge-impact-of-fibre-laser-machines-on-modern-industrial-manufacturing-processes

Section 2: Speed and Efficiency

In the competitive world of metal fabrication, every second counts. Fibre laser cutting technology is renowned for its rapid cutting speeds and exceptional efficiency, providing a competitive advantage to streamline production and maximize your output.

Rapid Cutting Speeds

When it comes to speed, fibre lasers leave traditional cutting methods like plasma or oxy-fuel in the dust. Their concentrated beams can slice through metal with astonishing velocity, especially on thinner materials. This accelerated cutting time translates directly into increased production capacity, allowing you to complete more jobs in less time.

Reduced Downtime

Time is money, and downtime is a business owner’s worst enemy. Fibre laser cutters are designed for reliability and low maintenance. With fewer consumable parts and longer component lifespans, you’ll experience minimal interruptions to your workflow. This increased uptime means your machine is consistently generating revenue, not sitting idle.

Optimizing Production Through Speed and Efficiency

The combined impact of speed and reliability on your overall efficiency cannot be overstated. Here’s a closer look at the benefits:

• Faster Turnaround Times: Accelerate project completion to meet tight deadlines and take on more orders.

• Increased Capacity: Handle a greater volume of work without necessarily expanding your workforce or floor space.

• Reduced Bottlenecks: Eliminate production delays caused by slower cutting processes.

Section 3: Versatility and Flexibility

In today’s dynamic manufacturing landscape, the ability to adapt quickly to changing customer demands is crucial. Fibre laser cutting machines offer unparalleled versatility and flexibility, empowering you to take on a wide range of projects and expand your service offerings.

Wide Material Range

One of the major advantages of fibre lasers is their ability to cut a vast array of metals. Whether you’re working with stainless steel, mild steel, aluminium, copper, brass, or even more nonmainstream metals, a fibre laser cutter can handle it with precision. This versatility eliminates the need for multiple specialised cutting tools and opens up your business to a wider range of clients.

Intricate Designs

Fibre lasers aren’t just about straight lines. Their highly focused beams allow for the creation of intricate shapes, complex geometries, and fine details that would be difficult, if not impossible, to achieve with traditional methods. This unlocks your design potential, enabling you to produce custom parts, artistic metalwork, and unique products that set you apart from the competition.

Adapting to Changing Needs

The flexibility of a fibre laser cutting machine extends beyond its immediate capabilities. As your business grows and your clientele evolves, your fibre laser cutter can adapt alongside you. Need to start working with a new type of metal? With potential adjustments to settings and parameters, your machine can likely handle it. Want to expand incorporate metal marking? Many fibre laser cutters have this inbuilt functionality.

The Benefits of Versatility

Let’s translate this versatility into tangible business benefits:

• Attract New Customers: Offer a wider range of services to a broader customer base.

• Increase Revenue Streams: Explore new markets and product niches.

• Streamline Production: Handle diverse projects with a single piece of equipment.

• Future-Proof Your Investment: Your fibre laser cutter can grow with your business.

Remember: When investing in a fibre laser cutter, it’s wise to factor in your potential future needs to ensure the machine offers the versatility and flexibility to meet the challenges and opportunities that lie ahead.

Section 4: Cost Savings and ROI

While the upfront investment in a fibre laser cutting machine might give you pause, it’s essential to look beyond the initial price tag. This technology can deliver substantial cost savings over a relatively short time and offer a compelling return on investment (ROI). Let’s break down the key areas where you could see significant savings:

Lower Operating Costs

Fibre lasers are renowned for their energy efficiency. They consume significantly less electricity than traditional cutting methods like plasma, translating into lower electricity bills and reduced operational costs. Additionally, their long-lasting components and minimal maintenance requirements further contribute to cost savings.

Minimal Material Waste

The precision offered by fibre laser cutters allows for incredibly tight nesting patterns and clean cuts, dramatically reducing scrap metal. This means you’re getting the most out of your raw materials, maximizing your resources and saving money on material costs.

Labor Cost Considerations

While fibre laser cutters often require less manual intervention than some traditional methods, it’s important to look at your overall labour picture. The increased speed and automation can free up skilled workers for other tasks, potentially increasing overall productivity without hiring additional staff.

Increased Revenue Potential

The ability to deliver faster turnaround times, take on more complex projects, and offer expanded services creates new opportunities to attract more clients and command higher prices for your work. This increased revenue potential is a significant factor when calculating your potential ROI.

Calculating Your ROI

To determine the potential ROI for your specific business, consider the following:

• Cost of Your Current Methods: Analyse how much you’re currently spending on cutting processes, including labour, energy, materials, and maintenance.

• Potential Savings: Estimate the expected savings in those areas based on the capabilities of a fibre laser cutting machine.

• Increased Revenue: Project potential new revenue streams made possible by the technology.

• Investment Timeframe: Determine how quickly you expect the investment to pay for itself and begin generating profit.

Important Note: Calculating ROI can be complex. Seeking guidance from a financial advisor or a reputable fibre laser machine supplier can help you make an informed decision that aligns with your business goals.

Section 5: Is a Fibre Laser Cutter Right for You?

By now, you’ve seen the impressive advantages fibre laser cutting machines offer. But the critical question remains: Is this technology the right investment for your specific metal fabrication business? Let’s break down the key factors to consider.

Assessing Your Needs

Before taking the leap, it’s vital to do an honest assessment of your business’s current and future requirements. Here are some guiding questions:

• Production Volume: Do you consistently handle a high volume of metal cutting work? Is your current equipment struggling to keep up?

• Material Types: What metals do you primarily work with? Are you looking to expand your material capabilities?

• Do you currently sub-contract your laser cutting to a third party? Factor in the increased cost, extended lead times, supply failure and potential quality issues.

• Complexity of Cuts: Do your projects frequently involve intricate designs or tight tolerances?

• Budget: While a significant investment, have you analysed the potential return on investment (ROI) for your business?

Weighing the Benefits vs. Costs

Investing in a fibre laser cutting machine comes with an upfront cost. It’s essential to weigh this against the long-term benefits it can bring to your business. Consider the following:

• Increased Productivity: Will the speed and efficiency gains justify the investment?

• Reduced Operating Costs: How much could you potentially save in energy, consumables, and labour costs?

• New Revenue Opportunities: Could the expanded capabilities attract new clients and higher-value projects?

• Competitive Advantage: Would a fibre laser cutter give you an edge over competitors with less advanced technology?

Beyond the Numbers

The decision isn’t purely financial. Here are some intangible benefits to factor in:

• Improved Quality: Will the superior precision enhance your reputation and customer satisfaction?

• Reduced Stress: Can reliable, high-performance equipment alleviate bottlenecks and production pressures?

• Innovation Potential: Will the machine spark new ideas and services for your business?

The Verdict?

There’s no one-size-fits-all answer. It’s crucial to carefully analyse your business’s unique situation and goals. If you’re looking to significantly boost production, streamline operations, expand your capabilities, and deliver superior quality, then a fibre laser cutting machine could be the transformative technology your business needs.

We at Logi Laser Engineering would be happy to talk through all the options and find a cost effective solution that meet your exact needs. Please contact us.